F-C-8015

September 18, 2010

September 18, 2010

F Rating — 1 Hr

T Rating — 3/4 Hr

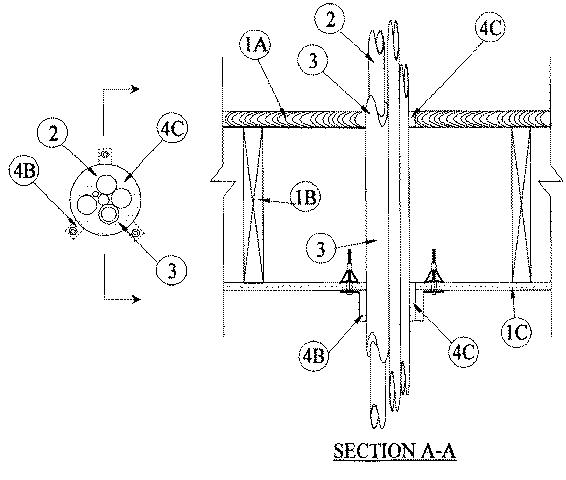

1.Floor-Ceiling Assembly — The 1 hr fire-rated wood joint floor ceiling assembly shall be constructed of the materials and in the manner specified in the individual L500 Designs in the UL Fire Resistance Directory, as summarized below:

A.Flooring System — Lumber or plywood subfloor with finish floor of lumber, plywood or Floor Topping Mixture* as specified in the individual Floor-Ceiling Design. Max diam of floor opening is 4-1/2 in.B.Wood Joists — Nom 10 in. deep (or deeper) lumber, steel or combination lumber and steel joists, trusses or Structural Wood Members* with bridging as required and with ends firestopped.C.Gypsum Board* — Nom 5/8 in. thick as specified in the individual Floor-Ceiling Design. Diam of opening to be max 1 in. larger than diam of bundled penetrants.

2.Through Penetrants — Max 3-1/2 in. diam bundle of pipes, conduits, tubing and/or cable to be installed within the opening. At the plywood subfloor, bundled penetrants to be installed either concentrically or eccentrically within the opening with an annular space of min 0 in. (point contact) to max 1 in. At gypsum ceiling, bundled penetrants to be installed either concentrically or eccentrically within the opening. Penetrants to be rigidly supported on both sides of the floor-ceiling assembly. The following types and quantity of penetrating items shall be utilized in the opening:

A.Metallic Penetrants — A max of one insulated and two uninsulated metallic pipes, conduits or tubing to be installed within the firestop system. The following types and sizes of metallic pipes, conduits or tubing may be used:

A1.Steel Pipe — Nom 1-1/4 in. diam (or smaller) Schedule 10 (or heavier) steel pipe.A2.Iron Pipe — Nom 1-1/4 in. diam (or smaller) cast or ductile iron pipe.A3.Conduit — Nom 1-1/4 in. diam (or smaller) steel electrical metallic tubing or steel conduit.A4.Copper Tubing — Nom 3/4 in. diam (or smaller) Type L (or heavier) copper tubing.A5.Copper Pipe — Nom 3/4 in. diam (or smaller) Regular (or heavier) copper pipe.B.Nonmetallic Penetrants — A max of two nonmetallic pipes, conduits or tubing to be installed within the opening. The following types and sizes of nonmetallic pipes or conduits may be used:

B1.Polyvinyl Chloride (PVC) Pipe — Nom 1-1/4 in. diam (or smaller) Schedule 40 solid core or cellular core PVC pipe for use in closed (process or supply) or vented (drain,waste or vent) piping system.B2.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 1-1/4 in. diam (or smaller) SDR 17 CPVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping system.B3.Rigid Nonmetallic Conduit+ — Nom 1-1/4 in. diam (or smaller) Schedule 40 PVC conduit installed in accordance with Article 347 of the National Electrical Code (NFPA 70).B4.Crosslinked Polyethylene (PEX) Tubing — Nom 1 in. diam (or smaller) SDR 9 PEX tubing for use in closed (process or supply) or vented (drain, waste or vent) piping systems.C.Cables — A max of two cables to be installed within the opening. The following types and sizes of copper conductor cables may be used:

C1.Max 25 pair No. 24 AWG (or smaller) telephone cable with (PVC) insulation and jacket. C2.Max 4/C No. 18 AWG (or smaller) thermostat cable with PVC insulation and jacket.

3.Tube Insulation — Plastics++ — Nom 1/2 in. thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing. Tube insulation to be utilized on a max of one metallic penetrating item (Item 2A).See Plastics++ (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and having a UL 94 Flammability Classification of 94-5VA may be used.

4.Firestop System — The firestop system shall consist of the following:

A.Forms — (Not Shown) — Used as a form to prevent leakage of fill material during installation. Forms to be cut or formed to fit the contour of the penetrating item and fastened to the underside of subfloor. Forms to be removed after fill material has cured.B.Firestop Device* — Nom 3 in. diam (or smaller) galv steel collar lined with an intumescent material sized such that the inside diam is max 1 in. larger than diam of bundled penetrants. Device shall be installed around bundled penetrants in accordance with the accompanying installation instructions. Device positioned concentric with opening and secured to bottom surface of gypsum wallboard ceiling by means of 3/16 in. diam steel hollow wall anchors in conjunction with 5/16 by 3/4 in. washers at each anchor tab.

RECTORSEAL — Metacaulk Pipe CollarC.Fill,Void or Cavity Material* — Caulk — Min 3/4 in. thickness of fill material applied within the annulus, flush with top surface of subfloor. Caulk also installed to completely fill interior of firestop device and annular space between bundled penetrants and gypsum ceiling. Caulk to be forced into interstices of bundled penetrants to max extent possible.

RECTORSEAL — Metacaulk 1000

ing

++Bearing the UL Recognized Component Marking