W-L-5310

July 13, 2015

July 13, 2015

F Ratings — 1 and 2 Hr (See Item 1)

T Ratings — 0 and 1 Hr (See Item 1)

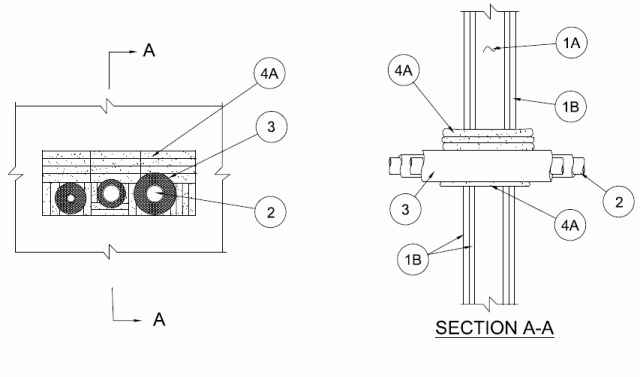

1.Wall Assembly — The 1 and 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U300, U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. (406 mm) OC. Steel studs to be min 3-1/2 in. (89 mm) wide and spaced max 24 in. (610 mm) OC.B.Gypsum Board* — 5/8 in. (16 mm) thick with square or tapered edged. The type, thickness, number of layers and fasteners shall be as specified in the individual Wall and Partition Design in the UL Fire Resistance Directory. Max size of opening is 144 in2 with a max dimension of 18 in. (457 mm).The hourly F Rating of the firestop system is equal to the hourly fire rating of the wall assembly in which it is installed. The hourly T Rating is 0 hr and 1 hr for 1 and 2 hr rated assemblies, respectively.

2.Through Penetrants — Max three tubes installed eccentrically or concentrically within opening. Tubes to be rigidly supported on both sides of wall assembly. The following types and sizes of metallic tubing may be used:

A.Aluminum Tubing — Reflok 6061-T4 ASTM B210 seamless aluminum tubing for use in closed (process or supply) piping systems. Tubing sizes shall be maximum 2-1/8 in. (54 mm) to minimum 1/4 in.(6 mm) outer diameter (OD) having wall thickness ranging from 0.080 in. (2 mm) to 0.030 in. (0.8 mm) respectively.

3.Pipe Covering — The following pipe covering shall be used with each Through Penetrant (Item 2).

A.Tube Insulation-Plastics+ — Min 1/2 in. (13 mm) thick to max 1-1/2 in. (38 mm) thick Aerocel Ethylene Propylene Diene Terpolymer (EPDM) pipe insulation furnished in the form of tubing. The annular space between the insulated penetrants and the edge of the opening shall be min 0 in. (point contact) to max 4 in. (102 mm). The annular space between insulated penetrants shall be min 5/8 in. (16 mm) to max 4 in. (102 mm).See Plastics+ - (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications of having a UL 94 Flammability Classification of 94-5VA may be used.

4.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* — Pillows — Max 6 in. (152 mm) long by 9 in. (229 mm) wide by 3 in. (76 mm) thick plastic covered intumescent pillows tightly packed into opening filling annular space between and around penetrants and between penetrants and periphery. Pillows installed with 9 in. (229 mm) dimension projecting through wall and centered within opening.

RECTORSEAL — Metacaulk Pillows, Biostop Pillows, FlameSafe PillowsB.Fill, Void or Cavity Material* - Caulk (Optional) — After installation of pillows, min 1/4 in. (6 mm) depth of fill material applied to seal any voids between pillows and periphery of opening, between pillows and through penetrants and between pillows on finished side of wall.

RECTORSEAL — Metacaulk 150+, Metacaulk 1000, Biostop BF 150+, Biostop 500+, FlameSafe FS1900