W-L-4058

September 25, 2001

September 25, 2001

F Rating — 1 & 2 Hr (See Item 1)

T Rating — 0 Hr

Leakage Rating At Ambient - Less Than 1 CFM/Sq. Ft

Leakage Rating At 400 F - 2 CFM/Sq. Ft

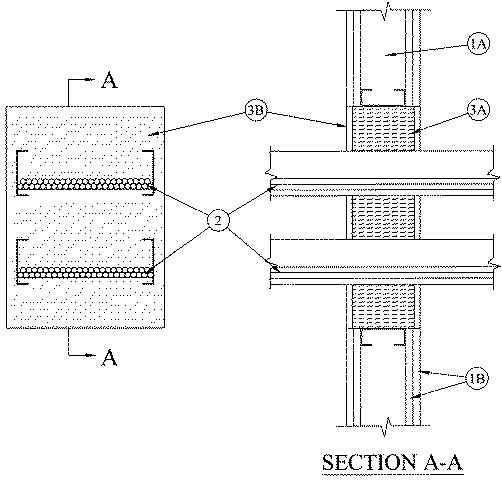

1.Wall Assembly — The 1 or 2 Hr fire-rated gypsum wallboard/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing to consist of min 3-1/2 in. wide steel channel studs spaced max 24 in. OC for 1 Hr rated walls. Steel studs to be min 2-1/2 in. wide and spaced max 24 in. OC for 2 Hr rated walls. Additional framing members to be installed in stud cavity containing cable tray to form a rectangular box around the opening.B.Gypsum Board* — One or two layers of nom 5/8 in. thick gypsum wallboard, as specified in the individual Wall and Partition Design. Max area of opening is 585 sq in. with max dimensions of 21 in. wide by 27-7/8 in. high.The hourly F Rating of the firestop system is equal to the hourly rating of the wall.

2.Cable Trays — A max of 2 cable trays are permitted per opening. Max 18 in. wide by max 4 in. deep open-ladder or solid-back steel or aluminum cable trays. The annular space between the cable trays and the periphery of opening shall be min 2 in. to max 7 in. The annular space between the cable trays shall be min 5-3/4 in. to max 11 in. Cable trays to be rigidly supported on both sides of wall assembly.

3.Cables — Aggregate cross-sectional area of cables in cable trays to be max 40 percent of the cross-sectional area of the cable tray based on a max 3.0 in. cable loading depth within the cable tray. Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 1/C 500 kcmil cable with cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC) jacket and insulation. B.Max 4/C No. 2 AWG cable with XLPE or PVC jacket and insulation. C.Max 12/C No. 12 AWG cable with XLPE or PVC jacket and insulation.

4.Firestop System — The firestop system shall consist of the following:

A.Packing Material — Min 4 in. thickness of min 4 pcf mineral wool batt insulation packed at 50 percent compression into opening as a permanent form. Packing material to be recessed from both surfaces of wall as required to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* - Caulk — Min 3/8 in. thickness of fill material applied within the annular space, flush with both surfaces of wall.

RECTORSEAL — Metacaulk 835+