W-L-4041

April 3, 2003

April 3, 2003

F Ratings —1 and 2 Hr

T Rating — 3/4 Hr

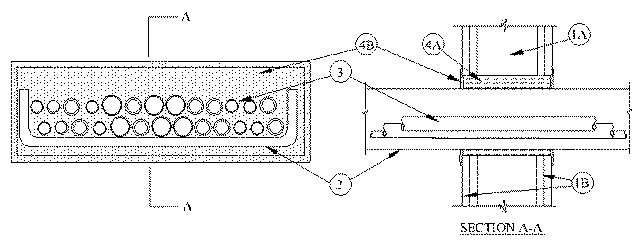

1.Wall Assembly — The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U300 or U400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. lumber spaced 16 in. OC. Steel studs to be min 3-1/2 in. wide and spaced max 24 in. OC. Additional framing members to be installed in stud cavity containing cable tray to form a rectangular box around the opening .B.Gypsum Board* — One or two layers of nom 5/8 in. thick gypsum board, as specified in the individual Wall and Partition Design. Max area of opening is 224 sq in. with max dimension of 28 in.The hourly F Rating of the firestop system is equal to the hourly fire rating of the wall assembly in which it is installed.

2.Cable Tray* — Max 24 in. wide by max 4 in. deep open ladder cable tray with channel-shaped side rails formed from 0.060 in. thick (No. 16 gauge) galv steel with nom 1 in. diam rungs spaced max 9 in. OC. The annular space between the cable tray and the periphery of the opening shall be min 1 in. to max 5 in. Cable tray to be rigidly supported on both sides of floor or wall assembly.

3.Cables — Aggregate cross-sectional area of cables in cable tray to be max 41 percent of the cross-sectional area of the cable tray based on a max 3 in. deep cable loading depth within the cable tray. Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 300 pair, No. 24 AWG copper conductor communication cable with polyvinyl chloride insulation and jacket material. B.Max - 25 pair, No.24 AWG copper conductor communication cable with polyvinyl chloride insulation and jacket material. C.Max 750 MCM power cables, THHN or THWN jacketed. D.Max 6 /C Commscope Oprtical Research 2001 fiber optic cable. E.Max 12/C Commscope Oprtical Research 2001 fiber optic cable. F.Max 8/C No. 12 AWG copper conductor Type THHN or THWN power cable.

4.Firestop System — The firestop system shall consist of the following:

A.Packing Material — Min 4-3/4 or 6 in. thickness of min 4 pcf mineral wool batt insulation firmly packed into opening as a permanent form in 1 or 2 hr walls, respectively, flush with both surfaces of wall.B.Fill, Void or Cavity Material* Sealant — Min 1/8 in. thickness of fill material applied over mineral wool on both surfaces of wall. Fill material to overlap 1/2 in. onto wall, cable tray and cables in cable tray. Additional fill material to be forced into cable interstices to max extent possible.

RECTORSEAL — Metacaulk 1200 Spray or Metacaulk 1200 Caulk Grade