W-L-3234

October 5, 2015

October 5, 2015

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

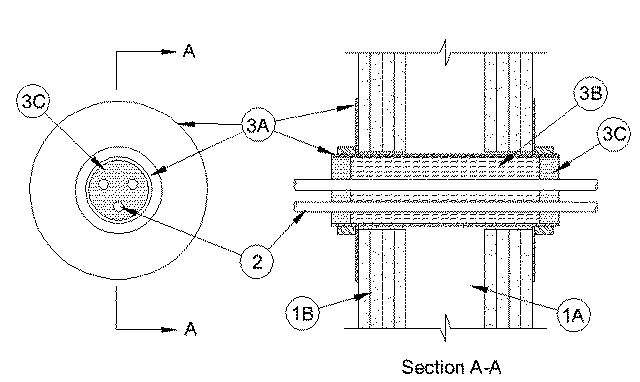

1.Wall Assembly — The 3 or 4 hr fire-rated gypsum board/steel stud wall assembly shall be constructed of the materials and in the manner specified in the individual U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing shall consist of steel channel studs. Steel studs to be min 3-5/8 in. (92 mm) wide and spaced 24 in. (610 mm) OC.B.Gypsum Board* — Multiple layers of min 1/2 in. (13 mm) thick gypsum board. The gypsum board type, thickness, number of layers and orientation shall be as specified in the individual Wall and Partition Design.The hourly F and FH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly in which it is installed.

2.Cables — Aggregate cross-sectional area of cables in sleeve to be min 8 to max 34 percent of the cross-sectional area of the sleeve. Cables to be tightly bundled. The annular space shall be min 1/4 in. (6 mm) to max 1-1/4 in. (32 mm). Cables to be rigidly supported on both surfaces of the wall assembly. Any combination of the following types and sizes of cables may be used:

A.Max RG59/U (or smaller) coaxial cable with fluorinated ethylene insulation and jacketing. B.Max 62.5/48 fiber optic cable with PVC insulation and jacket. C.Max 4 pair No. 24 AWG (or smaller) copper conductor data cable with PVC insulation and jacketing.

3.Firestop System — The firestop system shall consist of the following:

A.Firestop Device* — Threaded steel sleeve device incorporating flat washers secured by threaded couplers. Device shall be installed around cables in accordance with the accompanying installation instructions. Device provided in nom 1, 2 and 4 in. (25, 51 and 102 mm) sizes. Max diam of opening in wall for 1, 2 and 4 in. (25, 51 and 102 mm) size devices are 1-1/4, 2-7/16 and 4-1/2 in. (32, 62 and 114 mm) respectively.

UNIQUE FIRE STOP PRODUCTS INC — Threaded FirestopA1.Firestop Device* — (Not Shown) — As an alternate to the threaded sleeve device in Item 3A, threaded steel sleeve halves incorporating split nuts and split washers sized to fit the specific diam of the opening may be used. Device shall be installed around cables in accordance with the accompanying installation instructions. Device provided in nom 1, 2 and 4 in. (25, 51 and 102 mm) sizes. Max diam of opening in wall for 1, 2 and 4 in. (25, 51 and 102 mm) size devices are 1-1/4, 2-7/16 and 4-1/2 in. (32, 62 and 114 mm) respectively.

UNIQUE FIRE STOP PRODUCTS INC — Split SleeveB.Packing Material — Min 4 pcf (64 kg/m3) mineral wool batt insulation packed into opening as a permanent form throughout full length of firestop device except for recess at each end of the device to accommodate the required thickness of fill material.C.Fill Void or Cavity Materials* - Putty — Min 1 in. (25 mm) thickness of fill material applied within annulus, flush both ends of firestop device.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 618 Firestop Putty Stick

RECTORSEAL — Metacaulk Fire Rated Putty

SPECIFIED TECHNOLOGIES INC — SpecSeal Putty