W-L-3208

April 3, 2003

April 3, 2003

F Ratings — 1 and 2 Hr (See Item 1)

T Rating — 0 Hr

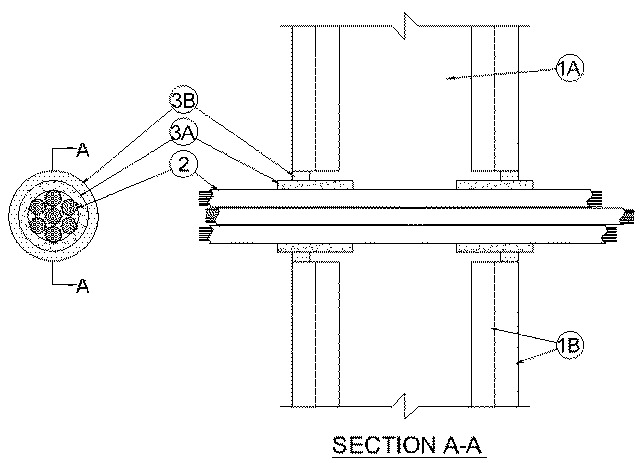

1.Wall assembly — The 1 or 2 hr fire rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner described in the individual U300 or U400 Series Wall or Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. lumber spaced 16 in. OC with nom 2 by 4 in. lumber end plates and cross braces. Steel studs to be min 3-5/8 in. wide by 1-3/8 in. deep channels spaced max 24 in. OC.B.Gypsum Board* — Nom 5/8 in. thick, 4 ft. wide with square or tapered edges. The gypsum board type, number of layers and sheet orientation shall be as specified in the individual Wall and Partition Design. Max diam of opening is 3 in.The hourly F Rating of the firestop system is equal to the hourly fire rating of the wall assembly in which it is installed.

2.Cables — Max 2 in. diam tight bundle of cables centered in circular cutouts in gypsum board and rigidly supported on both sides of wall assembly. Annular space between cable bundle and wall opening is max 1/2 in. Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 4 pair, No. 24 AWG telephone cable with polyvinyl chloride (PVC) insulation and jacket materials. B.Max 25 pair, No. 24 AWG telephone cable with polyvinyl chloride (PVC) insulation and jacket materials. C.Max 2/C No. 12 AWG MC (BX) cable with copper conductors and polyvinyl chloride (PVC) insulation. D.Max 4 pair, 24 AWG computer network cable with polyvinyl chloride (PVC) insulation and jacket materials. E.Max 2 cond., 14 AWG alarm coaxial cable with polyvinyl chloride (PVC) insulation and jacket materials. F.Max 3/C No. 12 AWG (or smaller) nonmetallic sheathed (Romex) cable with copper conductors, PVC insulation and jacket. G.Max 4/C No. 18 AWG bimetal conductors Type CL-2 (UL) Listed thermostat cable.

3.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* - Wrap Strip — One layer of nom 1/4 in. thick intumescent elastomeric material supplied in nom 2 in. wide strips. Wrap strip tightly wrapped around cable bundle with seam butted and secured with electrical tape. Wrap strip slid into annular space such that approx 1/4 in. of the wrap strip protrudes from the wall surface on each side of the wall assembly.

RECTORSEAL — Metacaulk Wrap StripB.Fill, Void or Cavity Materials* - Caulk — Min 1/4 in. thickness of caulk applied within the annular space between wrap strip and periphery of opening on each side of wall assembly. Caulk to be forced into the interstices of the cable bundle to the max extent possible within the confines of the wrap strip on each side of the wall assembly.

RECTORSEAL — Metacaulk 1000