W-L-3179

February 4, 2014

February 4, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

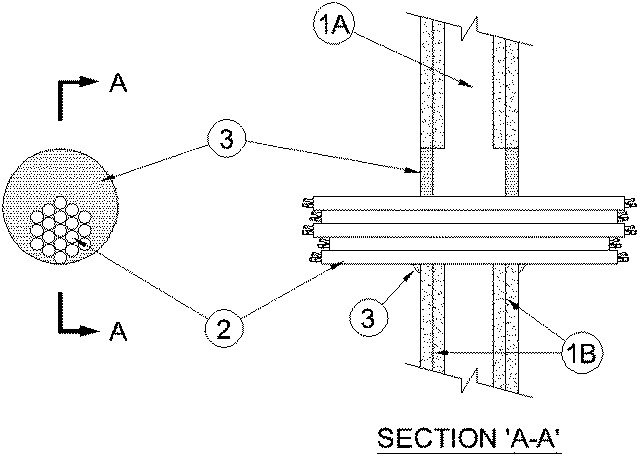

1.Wall Assembly — The 1 or 2 hr fire rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U300, U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features.

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. (406 mm) OC. Steel studs to be min 3-5/8 in. (92 mm) wide and spaced max 24 in. (610 mm) OC.B.Gypsum Board* — Min 5/8 in. (16 mm) thick, 4 ft (1.22 m) wide with square or tapered edges. Thickness, type, number of layers and fasteners as required in the individual Wall and Partition Design. Max diam of opening is 4 in. (102 mm).The hourly F and FHRatings of the firestop system are equal to the hourly fire rating of the wall assembly in which it is installed.

2.Cables — Max 2-3/4 in. (70 mm) diam tight bundle of cables to be installed either concentrically or eccentrically within the opening. Aggregate cross-sectional area of cables in opening to be max 41 percent of the cross-sectional area of the opening. The annular space between the cable bundle and the periphery of opening shall be min 0 in. (0 mm, point contact) to max 1-1/4 in. (32 mm). Any combination of the following types and sizes of cables may be used:

A.Max 3/C with ground No. 12 AWG (or smaller) copper conductor cable (12-3 Romex) with polyvinyl chloride (PVC) insulation and jacket. B.Max RG/6 No. 18 AWG Type CATV copper conductor coaxial cable with PVC insulation and jacket. C.Max 1/C - 350 kcmil (or smaller) cable with PVC or cross-linked polyethylene (XLPE) insulation and jacket. D.Max 400 pair No. 24 AWG copper telephone cables, with PVC insulation and jacket. E.Max 1/C - 350 kcmil (or smaller) cable with XLPE insulation and jacket. F.Max 4/C - No. 2/0 (or smaller) aluminum or copper conductor, aluminum or steel jacketed Metal-Clad or Armored-Clad Cable.+ G.Max 3/C (with ground) No. 2/0 AWG aluminum conductor service entrance cable with PVC insulation and jacket. H.Max 24 fiber 62.5/125 fiber optic cable with PVC insulation and jacket.

3.Fill, Void, or Cavity Materials* - Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush with each surface of wall. The sealant is also applied to fill all the interstices between the cables, prior to securing the bundle together, at both surfaces of wall. Additional sealant to be applied such that a min 3/8 in. (10 mm) bead is formed, at the point of contact of cable bundle and wall, on both surfaces of wall.

RECTORSEAL — FlameSafe® FS1900, Metacaulk 1000, Metacaulk 350i, Biostop 350i or Biostop 500+