October 27, 2016

F Ratings — 1 and 2 Hr (See Item 1)

T Ratings — 0, 1 and 2 Hr (See Items 1 and 3)

L Rating At Ambient — Less Than 1 CFM/sq ft

L Rating At 400 F — Less Than 1 CFM/sq ft

1.Wall Assembly — The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner described in the individual U300, U400, V400 or W400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. (406 mm) OC. Steel studs to be min 3-5/8 in. (92 mm) wide and spaced max 24 in. (610 mm) OC.

B.Gypsum Board* — 5/8 in. (16 mm) thick with square or tapered edges, The gypsum board type, thickness, number of layers, fastener type and sheet orientation shall be as specified in the individual U300, U400, V400 or W400 Series Design in the UL Fire Resistance Directory. Max diam of opening is 8 in. (203 mm) when Item 3A is used and max 7 in. (178 mm) when Item 3B is used.The hourly F and T Ratings of the firestop system are dependent on the hourly fire rating of the wall assembly in which it is installed. See Item 3 also for T Rating.

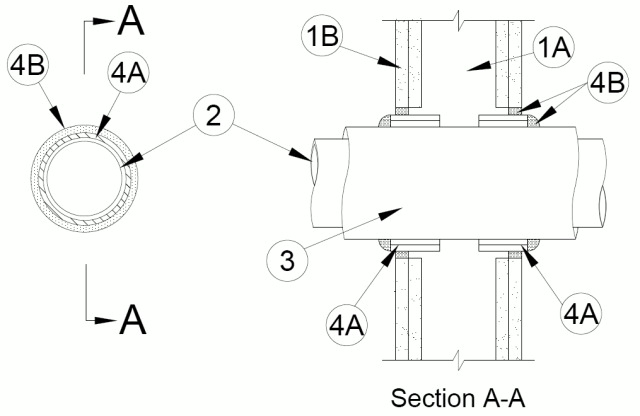

2.Through Penetrant — One nonmetallic tube to be installed within the firestop system. Tube to be rigidly supported on both sides of the wall assembly. The following types and sizes of nonmetallic tubes may be used:

A.Crosslinked polyethylene (PEX) Tubing — Nom 3 in. (76 mm) diam (or smaller) UPONOR - AquaPex SDR 9 tube for use in closed (process or supply) piping systems.

3.Pipe Covering* — One of the following types of pipe covering shall be used:

A.Pipe and Equipment Covering Materials* — Max 1-1/2 in. (38 mm) thick hollow cylindrical heavy density (min 3.5 pcf or 56 kg/m3) glass fiber units jacketed on the outside with an all service jacket. Longitudinal joints sealed with metal fasteners or factory-applied self-sealing lap tape. Transverse joints secured with metal fasteners or butt tape supplied with the product. The annular space between the insulated through penetrant and the periphery of the opening shall be min 3/4 in. (19 mm) to max 1 in. (25 mm). When thickness of insulation is less than 1-1/2 in. (38 mm), the T Rating of the firestop system is 0 hr.See Pipe and Equipment Covering Materials* (BRGU) category in the Building Materials Directory for names of manufacturers. Any pipe covering material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

B.Tube Insulation Plastics+ — Max 1 in. (25 mm) thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing. The annular space between the insulated through penetrant and the periphery of the opening shall be min 1/4 in. (6 mm) to max 1-1/2 in. (38 mm). When thickness of insulation is less than 1 in. (25 mm), the T Rating of the firestop system is 0 hr.See Plastics+ (QMFZ2) category in the Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and having a UL94 Flammability Classification of 94-54A may be used.

4.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* — Wrap Strip — Two layers of nom 1/4 in. (6 mm) thick by 2 in. (51 mm) wide intumescent wrap strip individually wrapped around the outer circumference of the insulated pipe with ends butted and held in place with tape or tie wire. Butted ends in successive layers shall be offset. Wrap strip shall be installed at both sides of opening. Wrap strip slid into annular space to extend nom 1/4 in. (6 mm) from both surfaces of wall.

RECTORSEAL — Metacaulk Wrap Strip, Biostop Wrap Strip, FlameSafe Wrap StripB.Fill, Void or Cavity Material* — Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus between wrap strip (Item 4A) and periphery of opening, flush with both surfaces of wall. In addition, min 1/2 in. (13 mm) bead of sealant shall be applied to cover the exposed ends of the wrap strip at both sides of wall.

RECTORSEAL — Metacaulk 1000, Biostop 500+, FlameSafe 1900