W-L-2632

August 29, 2016

August 29, 2016

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

- System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

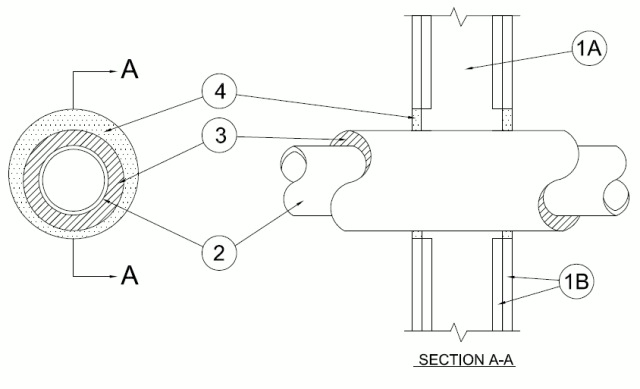

1.Wall Assembly — The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U300, U400 or V400 Series Wall or Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. (406 mm) OC. Steel channel studs to be min 3-1/2 in. (89 mm) wide and spaced max 24 in. (610 mm) OC.B.Gypsum Board* — Nom 5/8 in. (16 mm) thick, with square or tapered edges. The gypsum board type, number of layers, fastener type and sheet orientation shall be as specified in the individual Wall and Partition Design. Max diam of opening is 5 in. (127 mm).The hourly F, T, FH, FT and FTH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly.

2.Through Penetrant — One nonmetallic pipe to be installed either concentrically or eccentrically within the firestop system. Pipe to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipes may be used:

A.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 3/4 in. (19 mm) diam (or smaller) SDR11 CPVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 3/4 in. (19 mm) diam (or smaller) FLOWGUARD GOLD® SDR11 CPVC for use in closed (process or supply) or vented (drain, waste or vent) piping systems.

3.Pipe Covering* — Nom 1 in. (25 mm) thick hollow cylindrical heavy density (min 3.5 pcf) glass fiber units jacketed on the outside with an all service jacket. Longitudinal joints sealed with metal fasteners or factory-applied self-sealing lap tape. Transverse joints secured with metal fasteners or with butt tape supplied with the product. The annular space shall be min 1/2 in. (13 mm) to max 1-1/2 in. (38 mm).

See Pipe and Equipment Covering - Materials (BRGU) category in the Building Materials Directory for names of manufacturers. Any pipe covering material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

4.Fill, Void or Cavity Materials* — Caulk — Min 5/8 in. (16 mm) thickness of caulk applied within annular space flush with each surface of wall.

RECTORSEAL — Metacaulk 1000, Biostop 500+