December 6, 2023

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

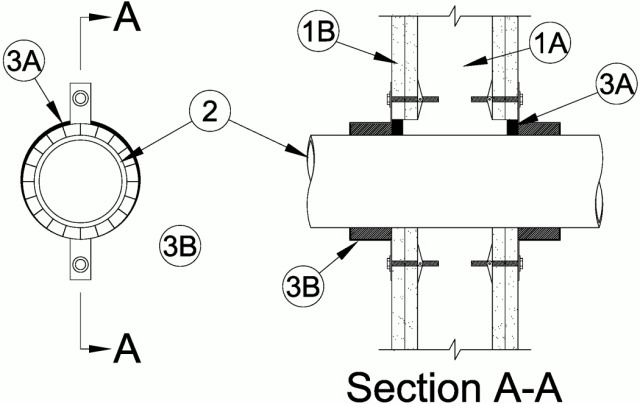

1.Wall Assembly — The 1 or 2 hr fire rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:A.Studs — Wall framing shall consist of min 3-1/2 in. (89 mm) wide steel channel studs spaced max 24 in. (610 mm) OC.B.Gypsum Board* — Thickness, type, number of layers and fasteners as required in the individual Wall and Partition Design. Wall opening to be max 5/8 in. (16 mm) larger than outside diam of nonmetallic pipe. Max diam of opening is 4 in. (102 mm).The F and FH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly in which it is installed.

2.Nonmetallic Pipe — One nom 3 in. (76 mm) diam (or smaller) nonmetallic pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems. Pipe to be installed either concentrically or eccentrically within the firestop system. The annular space between the pipe and periphery of opening shall be min 0 in. (point contact) to max 1/2 in. (13 mm). Pipe to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipe may be used:A.Polypropylene (PP) Pipe — Nom 2 in. (51 mm) diam (or smaller) Aquatherm Greenpipe SDR 7.4 with Faser PP pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.B.

Polypropylene (PP -RCT) Pipe — Nom 2 in. (51 mm) diam (or smaller) Niron CoolPro or Niron Clima SDR 7.4 PP-RCT pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.C.

Polypropylene (PP) Pipe — Nom 3 in. (76 mm) diam (or smaller) Aquatherm Greenpipe SDR 11 PP pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.D.

Polypropylene (PP -RCT) Pipe — Nom 3 in. (76 mm) diam (or smaller) Niron CoolPro or Niron Nero SDR 11 PP-RCT pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.E.

Polypropylene (PP) Pipe — Nom 3 in. (76 mm) diam (or smaller) Aquatherm Climatherm SDR 11 with Faser PP pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.F.

Polypropylene (PP -RCT) Pipe — Nom 3 in. (76 mm) diam (or smaller) Niron Clima SDR 11 PP-RCT pipe for use in closed (process or supply) or vented (drain, waste and vent) piping systems.G.

Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 3 in. (76 mm) diam (or smaller) ADR 13.5 CPVC pipe for use in closed (process or supply) piping systems.When max 2 in. (51 mm) diam pipe is used, the T, FT and FTH Ratings of the firestop system are 1/2 Hr when installed in 1 Hr fire rated wall and 1 Hr when installed in 2 Hr fire rated wall. When max 3 in. (76 mm) diam pipe is used, the T, FT and FTH Ratings of the firestop system are 0 Hr when installed in 1 Hr fire rated wall and 1/2 Hr when installed in 2 Hr fire rated wall.

3.Firestop System — The firestop system shall consist of the following:A.Fill, Void or Cavity Materials * - Caulk — Min 1/2 in. (13 mm) thickness of caulk applied within annulus, flush with both surfaces of wall assembly. When the annular space between the pipe and the edge of the wall opening is less than 1/4 in. (6 mm), use of the caulk in the annulus is optional.

RECTORSEAL — Type MC150+, 350i, 1000, 1100, 1200, FS900+, FS1900, FS4000B.Firestop Device* — Galv steel collar lined with an intumescent material sized to fit specific diam of the through penetrant. Devices to be installed around through penetrant on each side of the wall in accordance with accompanying installation instructions. Device incorporates anchor tabs for securement to the wall surface with 3/16 in. (5 mm) diam steel hollow wall anchors.

RECTORSEAL — Metacaulk Pipe Collar, Biostop Pipe Collar or Flamesafe Pipe CollarC.Fill, Void or Cavity Material* - Wrap Strip — (Not Shown) - As an alternate to Item 3B when max 2 in. (51 mm) diam pipe is used, single layer of nom 1/4 in. (6 mm) thick by 1 in. (25 mm) wide intumescent wrap strip wrapped around the outer circumference of the pipe on each side of the wall. Wrap strip installed with butted seam and such that edge of wrap strip is flush with the surface of wall. Wrap strip temporarily secured with tape or tie wire.

RECTORSEAL — Metacaulk Wrap Strip, Biostop Wrap Strip or Flamesafe Wrap StripD.Steel Collar — (Not Shown) - When Item 3C is used, a collar fabricated from coils of precut min 0.016 in. thick (0.41 mm) galv steel available from fill material manufacturer shall be installed to restrain wrap strip. Collar shall be nom 1 in. (25 mm) deep with 1 in. (25 mm) wide by 1-1/2 in. (38 mm) long anchor tabs for attachment to wall. In addition, collar provided with 1/2 in. (13 mm) wide by 3/4 in. (19 mm) long retainer tabs opposite the anchor tabs. Collar shall be wrapped over the wrap strip, overlapping min 1 in. (25 mm). The retainer tabs are folded 90 deg towards the pipe to maintain the annular space around the pipe and to retain the wrap strip. Collars secured to wall at three anchor tabs with Type G laminating screws or 3/16 in. (5 mm) diam steel hollow wall anchors in conjunction with 1/4 by 5/8 in. (6 by 16 mm) diam steel washers.