W-L-1152

February 20, 2019

February 20, 2019

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

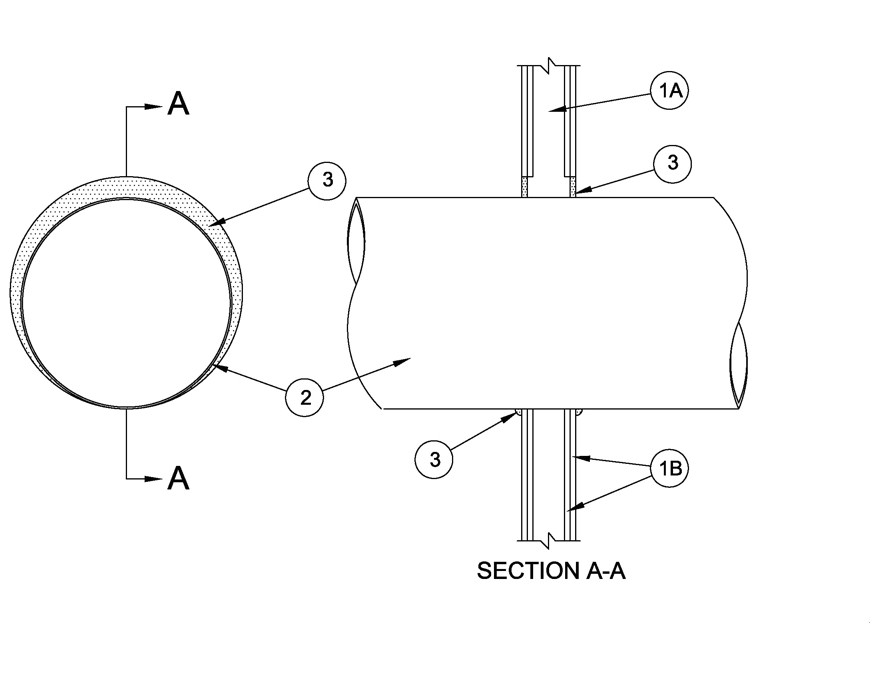

1.Wall Assembly — The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner described in the individual U300, U400, V400 or W400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. (406 mm) OC. Steel studs to be min 3-5/8 in. (92 mm) wide and spaced max 24 in. (610 mm) OC. When steel studs are used and the diam of opening exceeds the width of stud cavity, the opening shall be framed on all sides using lengths of steel stud installed between the vertical studs and screw-attached to the steel studs at each end. The framed opening in the wall shall be 4 to 6 in. (102 to 152 mm) wider and 4 to 6 in. (102 to 152 mm) higher than the diam of the penetrating item such that, when the penetrating item is installed in the opening, a 2 to 3 in. (51 to 76 mm) clearance is present between the penetrating item and the framing in all four sides.B.Gypsum Board* — 5/8 in. (16 mm) thick, 4 ft (1.2 m) wide with square or tapered edges. The gypsum board type, thickness, number of layers, fastener type and sheet orientation shall be as specified in the individual Design in the UL Fire Resistance Directory. Max diam of opening is 26-3/8 in. (670 mm) for steel stud walls. Max diam of opening is 14-1/2 in. (368 mm) for wood stud walls.The hourly F and FH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly in which it is installed.

2.Through Penetrant — One metallic pipe, conduit or tubing to be installed either concentrically or eccentrically within the firestop system. The annular space between pipe, conduit or tubing and periphery of opening shall be min 0 in. (point contact) to max 2-3/8 in. (60 mm). Pipe, conduit or tubing to be rigidly supported on both sides of wall assembly. The following types and sizes of metallic pipes, conduit or tubing may be used:

A.Steel Pipe — Nom 24 in. (610 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe.B.Iron Pipe — Nom 24 in. (610 mm) diam (or smaller) cast or ductile iron pipe.C.Conduit — Nom 4 in. (102 mm) diam (or smaller) steel electrical metallic tubing or nom 6 in. diam (or smaller) steel conduit.D.Copper Tubing — Nom 6 in. (152 mm) diam (or smaller) Type L (or heavier) copper tubing.E.Copper Pipe — Nom 6 in. (152 mm) diam (or smaller) Regular (or heavier) copper pipe.

3.Fill, Void or Cavity Material* — Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within annulus, flush with both surfaces of wall. At the point contact location between through penetrant and gypsum board, a min 3/8 in. (10 mm) diam bead of fill material shall be applied at the gypsum board/through penetrant interface on both surfaces of wall.

RECTORSEAL — FlameSafe FS900, FS900+, FS1900, Metacaulk MC 150+, Metacaulk 1000, Metacaulk 350i, Biostop BF 150+, Biostop 350i or Biostop 500+