W-L-0008

November 18, 1997

November 18, 1997

F Rating — 2 Hr

T Rating — 2 Hr

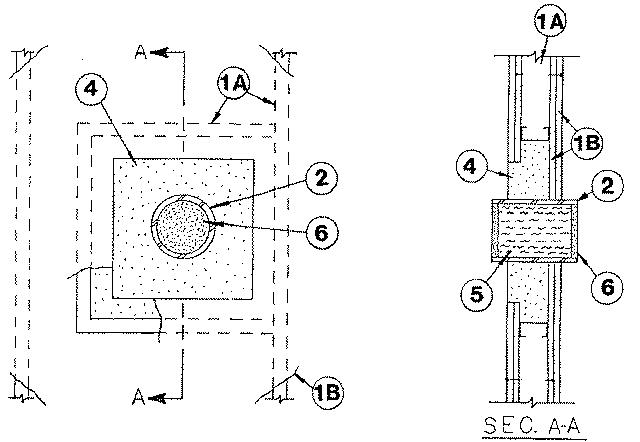

1.Wall Assembly — The fire rated gypsum wallboard/stud wall assembly shall be constructed of the materials and in the manner specified in the individual U300 or U400 Series Wall and Partition Designs in the Fire Resistance Directory and shall include the following construction features:

A.Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. lumber spaced 16 in. OC. Steel studs to be min 3-5/8 in. wide and spaced max 24 in. OC. Additional framing members to be installed in stud cavity containing the through-penetrating item to form a square or rectangular box around the penetrant with the dimensions of the framed opening being min 17 by 17 in. and with at least one side of the frame being comprised of a wall stud.B.Gypsum Board* — Two layers of nom 5/8 in. thick gypsum wallboard, as specified in the individual Wall and Partition Design. Max diam of opening is 6-1/2 in.

2.Metallic Sleeve — Nom 6 in. diam by 8 in. long Schedule 40 (or heavier) steel pipe sleeve inserted in nom 6-1/2 in. diam circular opening cut through both layers of gypsum wallboard on one side of the wall assembly and centered in a nom 13 by 13 in. opening on the other side of the wall assembly. Steel sleeve to be installed such that 1 in. extends beyond both surface of the wall assembly.

3.Forms — (Not Shown) — Used as a form to prevent leakage of fill material during installation. Forms to be a rigid sheet material, cut to fit the contour of the sleeve and fastened to the both sides of wall. Forms to be removed after fill material has cured.

4.Fill, Void or Cavity Material* — Mortar — Min 4-7/8 in. thickness of fill material applied to fill framed cavity, flush with wall surfaces containing the nom 13 by 13 in. opening. Material to be mixed with water in accordance with the mixing instructions on the bag and pumped or troweled into the framed cavity.

RECTORSEAL — Bio K2 or Bio K10 Mortar

5.Packing Material — Min 7-1/2 in. thickness of ceramic (alumina silica) fiber blanket or min 8.0 pcf mineral wool batt insulation firmly packed into the opening as a permanent form. Packing material to be recessed from both surfaces of wall as required to accommodate the required thickness of fill material.

6.Fill, Void or Cavity Materials* — Caulk — Min 1/4 in. thickness of fill material applied to each end of the steel sleeve.

RECTORSEAL — Metacaulk 835+