W-J-8032

April 15, 2016

April 15, 2016

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

- System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

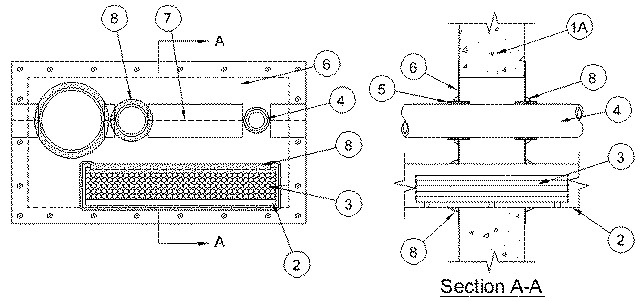

1.Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max size of opening is 30 in. (762 mm) by 30 in. (762 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Cable Tray — Max 18 in. (457 mm) wide by max 4 in. (102 mm) deep open-ladder cable tray with channel-shaped side rails formed of min 0.13 in. (3 mm) thick fiberglass with nom 2 in. (51 mm) wide rungs spaced 9 in. (229 mm) O.C. or max 18 in. (457 mm) wide by max 4 in. (102 mm) deep open ladder steel or aluminum cable tray. The min annular space between the cable tray and the periphery of opening shall be 1 in. (25 mm). The max annular space between the cable tray and the side periphery of the opening shall be 10 in. (254 mm). Cable tray to be rigidly supported on both sides of wall assembly.

3.Cables — Max 40 percent fill (based on a 3 in. or 76 mm loading depth within the cable tray) of any combination of cables. The following types of cables may be used in the cable tray:

A.Max 750 kcmil single conductor power cables; THHN or THWN jacketed. B.Max 8C, No.12 AWG multiconductor power and control cables; PVC jacketed. C.Multiple fiber optical communication cable jacketed with PVC. D.Max 300 pr No. 24 AWG telephone cable with PVC insulation and jacket.

The above types of cable may also be used in a max 2 in. (51 mm) diam tightly-bundled through penetrant independent of the cable tray. Cable bundle to be spaced a min of 8 in. (203 mm) from the periphery of opening and a min of 6 in. (152 mm) from other through-penetrants. The space between the cable bundle and periphery of opening shall be min 0 in. (point contact) to a max of 3/8 in. (10 mm). Cables to be tightly bundled together and rigidly supported on both sides of wall assembly.

4.Metallic Through Penetrants — Two metallic pipes, conduits or tubing to be installed within the opening. The space between metallic pipes, conduits or tubing shall be min 1 in. (25 mm). The space between metallic pipes, conduits or tubing and periphery of opening shall be min 1 in. (25 mm). Of the two metallic through penetrants, only one through penetrant shall have a nom diam greater than 4 in. (102 mm). Pipe, conduit or tubing to be rigidly supported on both sides of wall assembly. The following types and sizes of pipes, conduits or tubing may be used:

A.Steel Pipe — Nom 8 in. (204 mm) diam (or smaller) Schedule 5 (or heavier) steel pipe.B.Iron Pipe — Nom 8 in. (204 mm) diam (or smaller) cast or ductile iron pipe.C.Conduit — Nom 8 in. (204 mm) diam (or smaller) steel electrical metallic tubing or steel conduit.D.Copper Tubing — Nom 4 in. (102 mm) diam (or smaller) Type L (or heavier) copper tubing.E.Copper Pipe — Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.

5.Nonmetallic Through Penetrant — One nonmetallic pipe or conduit to be installed within the opening. The space between the nonmetallic pipe or conduit and periphery of opening shall be min 1 in. (25 mm). The space between the nonmetallic pipe and other through penetrants shall be min 6 in. (152 mm). Pipe or conduit to be rigidly supported on both sides of wall assembly. The following types of pipe or conduit may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 cellular core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.IChlorinated Polyvinyl Chloride (CPVC) Pipe- — Nom 2 in. (51 mm) diam (or smaller) SDR 13.5 CPVC pipe for use in closed (process or supply) piping systems.C.Rigid Nonmetallic Conduit+ — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 PVC conduit installed in accordance with Article 347 of the National Electrical Code (NFPA No. 70).

6.Fill, Void or Cavity Materials* — Wrap Strip — Single layer of nom 1/4 in. (6 mm) thick by 2 in. (51 mm) wide wrap strip installed around nonmetallic pipe on each side of wall. Wrap strip installed with butted seam and held in place with masking tape. Wrap strips installed to project 1 in. (25 mm) from the surface of the composite sheet (Item 7).

RECTORSEAL — Metacaulk Wrap Strip

7.Fill, Void or Cavity Materials* — Composite Sheet — Rigid aluminum foil-faced intumescent sheet with steel backer. Sheets cut to tightly follow the contour of the through-penetrants. Sheets cut to lap a min of 2 in. (51 mm) onto wall surface around periphery of opening and installed on both sides of wall assembly. Sheet to be installed with the steel backer exposed (aluminum foil facing against wall surface) and secured to wall surface with min 3/16 in. (5 mm) diam by 1-1/4 in. (32 mm) long masonry anchors, in conjunction with min 1 in. (25 mm) diam steel washers. Max spacing of fasteners not to exceed 6 in. (152 mm) OC and 2 in. (51 mm) max from ends, with additional fasteners located on each side of butted seams or slits (see Item 8) made to permit installation or the sheet around the cable tray.

RECTORSEAL — Metacaulk Composite Sheet

8.Cover Strip — Min 3 in. (76 mm) wide strip of min 0.019 in. (0.5 mm) thick (26 ga) stainless steel centered over entire length of the butted seam or slit made in the composite sheet. Cover strip secured to steel backer of composite sheet with steel sheet metal screws spaced max 3 in. (76 mm) OC on each side of seam or slit.

9.Fill, Void or Cavity Materials* — Caulk — Min 1/2 in. (13 mm) diam bead of caulk around nonmetallic through penetrant at the wrap strip / composite sheet surface interface on both sides of the wall. Min 1/2 in. (13 mm) diam bead of caulk around cable bundle and metallic through penetrant / composite sheet interface on both sides of the wall. Min 1/4 in. (6 mm) diam bead of caulk at the steel cover strip overlap and composite sheet overlap perimeter.

RECTORSEAL — Metacaulk 1000