W-J-8030

February 3, 2005

February 3, 2005

F Rating - 2 Hr

T Rating - 1 Hr

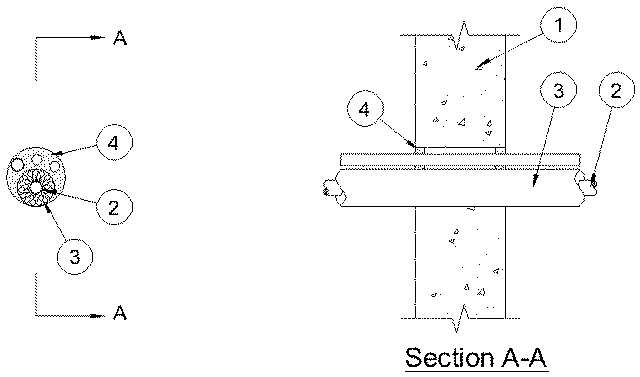

1.Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight 100-150 pcf (1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 4 in. (101 mm).

2.Metallic Penetrants — A max of two pipes or tubes installed eccentrically or concentrically within the opening. Annular space between penetrants and periphery of opening to be min 0 in. (point contact) to max 1-7/8 in. (48 mm). Separation between penetrants to be min 0 in. (point contact) to max 1/2 in. (13 mm). Penetrants to be rigidly supported on both sides of the wall. The following types and sizes of penetrants may be used:

A.Copper Tubing — Nom 1 in. (25 mm) diam (or smaller) Type L (or heavier) copper tubing.B.Copper Pipe — Nom 1 in. (25 mm) diam (or smaller) Regular (or heavier) copper pipe.C.Steel Pipe — Nom 1 in. (25 mm) (or smaller) Schedule 5 (or heavier) steel pipe.D.Iron Pipe — Nom 1 in. (25 mm) (or smaller) cast or ductile iron pipe.

3.Cables — Max of two cable lengths installed eccentrically or concentrically within the opening. Annular space between penetrants and periphery of opening to be min 0 in. (point contact) to max 1 7/8 in. (48 mm). Separation between penetrants to be min 0 in. (point contact) to max 1/2 in. (13 mm). Penetrants to be rigidly supported on both sides of the wall. The following types and sizes of penetrants may be used:

A.Cables — Max 8/C No. 12 AWG multiconductor power and control cable with XLPE or PVC insulation and PVC jacket.

4.Tube Insulation-Plastics+ — Nom 3/4 in. (19 mm) thick (or less) acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing. The tube insulation may be installed on a max of one pipe or tube. Annular space between the tube insulation and periphery of opening to be min 0 in. (point contact) to max 1-1/4 in. (32 mm). Space between insulated and uninsulated penetrants to be 0 in. (point contact) to max 1/4 in. (6 mm).

See Plastics (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and having a UL 94 Flammability Classification of 94-5A may be used.

5.Fill, Void or Cavity Materials* - Caulk — Min 5/8 in. (16 mm) thickness of caulk applied within annulus, flush with both surfaces of wall assembly.

RECTORSEAL — MC 150+