W-J-7176

June 5, 2019

June 5, 2019

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

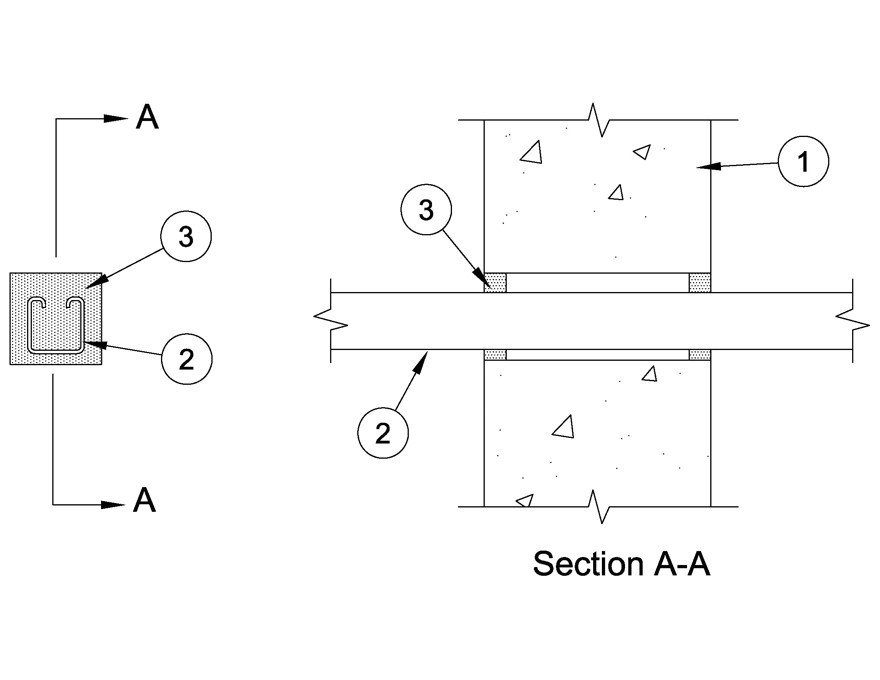

1.Wall Assembly — Min 6 in. (152 mm) thick lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 3-3/8 in. (86 mm). Max area of rectangular opening is 8.94 in2. (58 cm2) with max dimension of 3-3/8 in. (86 mm).

See Concrete Blocks (CAZT) in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — One metallic strut, cable or rod service support to be installed within the firestop system. An annular space of min 1/8 in. (3 mm) to max 7/8 in. (22 mm) is required within the firestop system. Strut, cable or rod service support to be rigidly supported on both sides of wall assembly. The strut, cable or rod service support may be installed at an angle not greater than 45 degrees from the perpendicular. The following types and sizes of metallic strut, cable or rod service support may be used:

A.Steel Strut — Max 1-5/8 by 1-5/8 in. (41 by 41 mm) channel strut formed from min 0.105 in. (2.7 mm) thick galv or painted steel.B.Steel Strut — Max 3-1/4 by 1-5/8 in. (83 by 41 mm) H strut formed from min 0.105 in. (2.7 mm) thick galv or painted steel.C.Cable — Max 3/8 in. (9.5 mm) diam unjacketed galv steel cable.D.Threaded Rod — Max 5/8 in. (16 mm) diam galv steel threaded rod.E.Steel Angle — Max 2 by 2 in. (51 by 51 mm) by min 0.105 in. (2.7 mm) thick galv or painted steel.

3.Fill, Void or Cavity Material* - Caulk or Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus and within the channel struts, flush with both surfaces of wall.

RECTORSEAL —Metacaulk 1000, Metacaulk MC 150+, Biostop 500+, Biostop BF 150+, FlameSafe FS900+ or FlameSafe FS 1900