W-J-7096

May 29, 2007

May 29, 2007

F Rating — 2 Hr

T Rating — 0 Hr

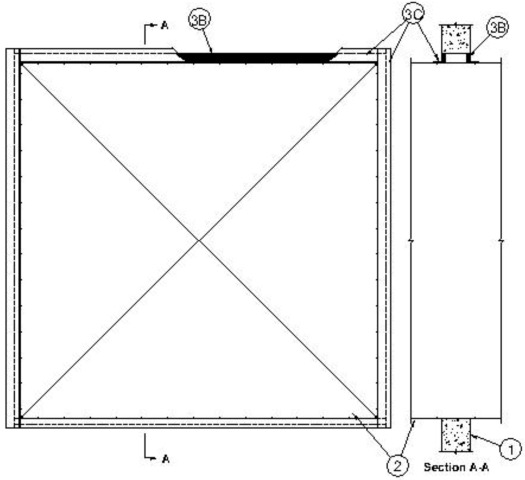

1.Wall Assembly — Min 6 in. (152 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max size of opening is 76.2 sq ft (7 m2) with a max width of 105-1/2 in. (268 cm).

See Concrete Blocks (CAZT) category in Fire Resistance Directory for names of manufacturers.

2.Steel Duct — Max 100 in. by 100 in. (2.5 by 2.5 m) galv steel duct to be installed either concentrically or eccentrically within the firestop system. The duct shall be constructed and reinforced in accordance with SMACNA construction standards. The space between the steel duct and periphery of opening shall be min 0 in. (point contact) to max 2 in. (51 mm). Steel duct to be rigidly supported on both sides of the wall assembly.

3.Firestop System — The firestop system shall consist of the following:

A.Packing Material — (Optional, Not Shown) — Polyethylene backer rod, mineral wool batt insulation or fiberglass batt insulation friction fitted into annular space. Packing material to be recessed from both surfaces of wall to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* — Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush with both surfaces of wall. Min 1/4 in. (6 mm) diam bead of fill material shall be applied at the point contact location between the steel duct and the gypsum board.

RECTORSEAL — Metacaulk 1000C.Steel Retaining Angles — Min No. 16 gauge galv steel angles sized to lap steel duct a min of 2 in. (51 mm) and to lap wall surfaces a min of 1 in. (25 mm). Angles attached to steel duct on both sides of wall with min No. 10 by 1/2 in. (13 mm) long steel sheet metal screws located a max of 1 in. (25 mm) from each end of steel duct and spaced a max of 6 in. (152 mm) OC.