W-J-7075

July 16, 2014

July 16, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

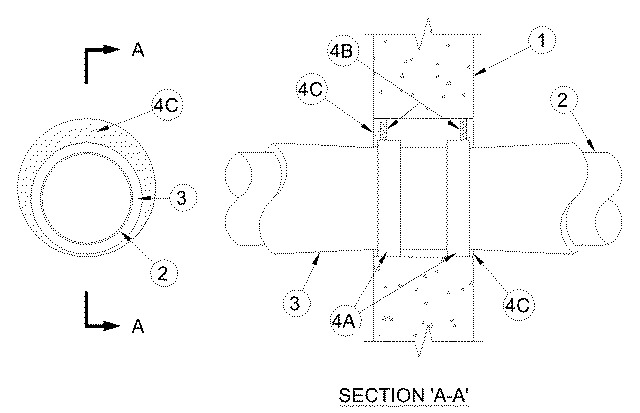

1.Wall Assembly — Min 4-7/8 in. and 6-1/8 in. thick lightweight or normal weight (100-150 pcf) concrete for 1 and 2 hr rated assemblies, respectively. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 23 in.

See Concrete Blocks (CAZT) in Volume 1 of the Fire Resistance Directory for names of manufacturers.

The hourly T Rating is 1/2 hr and 1 hr for 1 and 2 hr rated assemblies, respectively.

2.Steel Air Duct — Nom 20 in. diam(or smaller) , 28 gauge (or heavier) galv steel air duct to be installed either concentrically or eccentrically within the opening. Duct to be rigidly supported on both sides of wall assembly.

3.Duct Insulation* — Nom 1-1/2 in thick glass fiber blanket insulation jacketed on the outside with foil-scrim-kraft facing. Longitudinal and transverse joints sealed with foil-scrim kraft tape. The annular space between the wrap strip (item 4A) and the periphery of the opening shall be min 0 in. (point of contact) to max 1-1/8 in.See Batts and Blankets (BKNV) category in the Building Materials Directory for names of manufacturers. Any batts and blankets material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

4.Firestop System — The firestop system shall consist of the following:

A.Wrap Strip — One layer of nom 1/4 in. thick intumescent material supplied in 1-1/2 in. wide strips tightly wrapped around duct insulation, with a max insulation compression ratio of 50%, and held in place with masking tape. Wrap strip slid into annulus on both sides of wall such that wrap strip is recessed 5/8 in. from both surfaces of wall.

RECTORSEAL — FlameSafe Wrap StripB.Packing Material — (Optional) — Mineral wool or fiberglass insulation or foam backer rod compressed and firmly packed into annular space from each end of opening and recessed 5/8 in. from each wall surface.C.Fill, Void or Cavity Material* - Sealant — Min 5/8 in. thickness of fill material applied within annulus, flush with both surfaces of wall assembly.

RECTORSEAL — FS 900+ Sealant, Metacaulk MC 150+, Biostop BF 150+