W-J-7016

January 18, 1999

January 18, 1999

F Rating — 2 Hr

T Rating — 0 Hr

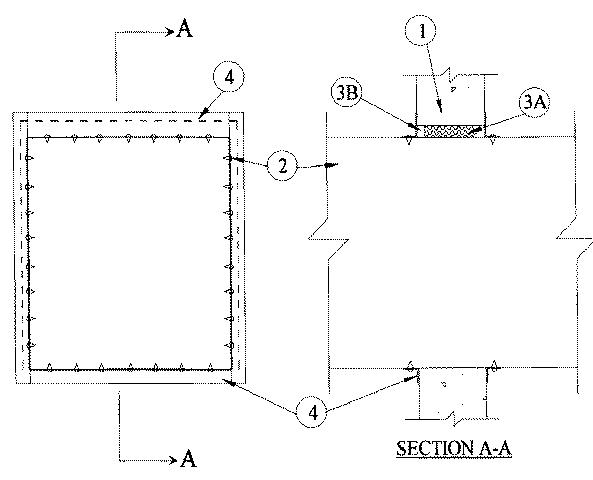

1.Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max size of opening is 484 sq in. with a max dimension of 22 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Steel Duct — Nom 21 by 21 in. (or smaller) No. 24 gauge (or heavier) steel duct to be installed either concentrically or eccentrically within the opening. The annular space shall be min 0 in. (point contact) to max 1 in. Duct to be rigidly supported on both sides of wall assembly.

3.Firestop System — The firestop system shall consist of the following:

A.Packing Material — Min 4 in. thickness of min 4 pcf mineral wool batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from both surfaces of wall as required to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* — Caulk — Min 1/2 in. thickness of fill material applied within the annulus, flush with both surfaces of wall. At point contact location, a min 1/4 in. diam bead of fill material shall be applied to the wall/duct interface on both surfaces of the wall.

RECTORSEAL — Metacaulk 1000

4.Steel Retaining Angles — Nom 2 by 2 in. by No. 22 gauge (or heavier) steel angles attached to all four sides of duct on both sides of wall. The angles shall be attached to the duct with No. 8 (or larger) sheet metal screws spaced max 2 in. from each end of duct and spaced a max of 5 in. OC.