W-J-5157

July 13, 2015

July 13, 2015

F Rating —2 Hr

T Rating —1 Hr

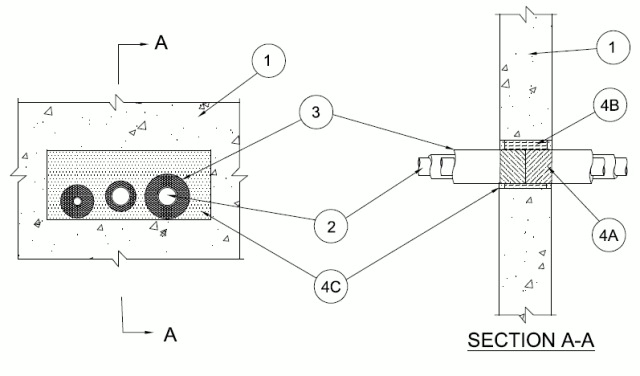

1.Wall Assembly — Min 6 in. (152 mm) thick lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max size of opening is 144 in2 with a max dimension of 18 in. (457 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — Max three tubes installed eccentrically or concentrically within opening. Tubes to be rigidly supported on both sides of wall assembly. The following types and sizes of metallic tubing may be used:

A.Aluminum Tubing — Reflok 6061-T4 ASTM B210 seamless aluminum tubing for use in closed (process or supply) piping systems. Tubing sizes shall be maximum 2-1/8 in. (54 mm) to minimum 1/4 in.(6 mm) outer diameter (OD) having wall thickness ranging from 0.080 in. (2 mm) to 0.030 in. (0.8 mm) respectively.

3.Pipe Covering — The following pipe covering shall be used with each Through Penetrant (Item 2).

A.Tube Insulation-Plastics+ — Min 1/2 in. (13 mm) thick to max 1-1/2 in. (38 mm) thick Aerocel Ethylene Propylene Diene Terpolymer (EPDM) pipe insulation furnished in the form of tubing. The annular space between the insulated penetrants and the edge of the opening shall be min 0 in. (point contact) to max 4 in. (102 mm). The annular space between insulated penetrants shall be min 5/8 in. (16 mm) to max 4 in. (102 mm).See Plastics+ - (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications of having a UL 94 Flammability Classification of 94-5VA may be used.

4.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* - Joint Strip — Three layers of 2 mm thick by 3 in. (76 mm) wide intumescent joint strip tightly wrapped around the outer circumference of each insulated pipe with ends butted and held in place with tape. Joint strip recessed into annular space at both sides of wall with edge of joint strip flush with each side of the wall.

RECTORSEAL — Metacaulk Joint Strip, Biostop Joint Strip, FlameSafe Joint StripB.Packing Material — Min 4-3/4 in. (121 mm) thickness of min 4 pcf (56 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from both surfaces of wall to accommodate the required thickness of fill material.C.Fill, Void or Cavity Material* - Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush with both surfaces of wall.

RECTORSEAL — Metacaulk 150+, Metacaulk 1000, Biostop BF 150+, Biostop 500+, FlameSafe FS1900