W-J-4017

January 18, 1999

January 18, 1999

F Rating — 2 Hr

T Rating — 0 Hr

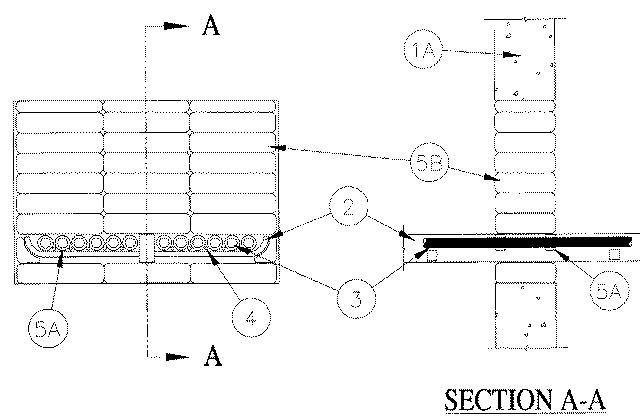

1.Wall Assembly — Min 6 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. If a single cable tray is utilized, the max area of opening is 540 sq in. with max dimension of 30 in. If two cable trays are installed side by side, the max area of opening is 1080 sq in. with max dimension of 60 in. If two cable trays are stacked vertically, the max area of opening is 780 sq in. with max dimension of 30 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Cable Tray* — Max 24 in. wide by 4 in. deep spine cable tray. The 1-1/2 in. wide by 2-3/4 in. deep tubular spine to be formed of min 0.130 in. and 0.080 in. thick extruded aluminum on the horizontal and vertical sides of the tube, respectively. A max of two cable trays to be installed in opening, either side by side or stacked vertically. The annular space between top and bottom of cable trays and periphery of opening shall be min 1 in. The annular space between sides of cable trays and periphery of opening shall be min 1/2 in. The spacing between adjacent cable trays shall be min 1 in. Cable trays to be rigidly supported on both sides of wall assembly. Aggregate cross-sectional area of all penetrating items (Items 3, 4 and 4A) within cable tray shall be 40 percent based upon a max 3 in. cable loading depth within the tray.

3.Nonmetallic Penetrants — One or more nonmetallic penetrants may be utilized within the opening. Min separation between nonmetallic penetrants is 1/2 in. Any combination of the following types and sizes of nonmetallic penetrants may be used:

A.Electrical Nonmetallic Tubing (ENT)+ — Nom 1-1/2 in. diam (or smaller) Electrical Nonmetallic Tubing+. ENT installed in accordance with Article 331 of the National Electrical Code (NFPA No. 70).See Electrical Nonmetallic Tubing (FKHU) category in the Electrical Construction Material Directory for names of manufacturers.

B.Optical Fiber Raceways+ — Nom 1 in. diam (or smaller) Optical Fiber Raceways+. Optical fiber raceway installed in accordance with Article 770 of the National Electrical Code (NFPA No. 70).See Optical Fiber Raceway (QAZM) category in the Electrical Construction Material Directory for names of manufacturers.

4.Cables — Individual bundles, each containing a max four cables installed between nonmetallic penetrants. Min separation between cable bundles and nonmetallic penetrants is 1/4 in. Adjacent cable bundles shall be separated by a min of one pillow (Item 5B). Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 25 pr No. 24 AWG telephone cables with polyvinyl chloride (PVC) insulation and jacket. B.Max 4 pr No. 24 AWG plenum rated telephone cables. C.RG6/U coax cable with polyethylene (PE) insulation and PVC jacket. D.Max 2 conductor No. 22 AWG stranded conductor alarm cable with polyvinyl chloride (PVC) insulation and jacket.

4A.Cables — (Not Shown) — Max 2-1/2 in. diam bundles of max 4 pr No. 24 AWG plenum cables may be installed within the cable tray. Adjacent cable bundles, or cable bundles and nonmetallic penetrants shall be separated by a min of one pillow (Item 5B).

5.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Materials* — Wrap Strip — Nom 1/4 in. thick by 1 in. wide intumescent wrap strip. Wrap strip is continuously wrapped around the outer circumference of each nonmetallic penetrant once and held in place with two wraps of electrical tape. Wrap strip to be installed flush with both surfaces of wall.

RECTORSEAL — Metacaulk Wrap StripB.Fill, Void or Cavity Material* — Pillows — Max 9 in. long by 6 in. wide by 2 in. thick plastic covered intumescent pillows tightly packed into opening. Pillows tightly packed to fill the annular space between cable trays, nonmetallic penetrants and/or cable bundles and periphery of opening, and between cable trays, nonmetallic penetrants and/or cable bundles. Pillows installed with 6 in. dimension projecting through wall.

RECTORSEAL — Metacaulk Pillows

*Bearing the UL Classification Marking

ing