W-J-3102

February 5, 2014

February 5, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

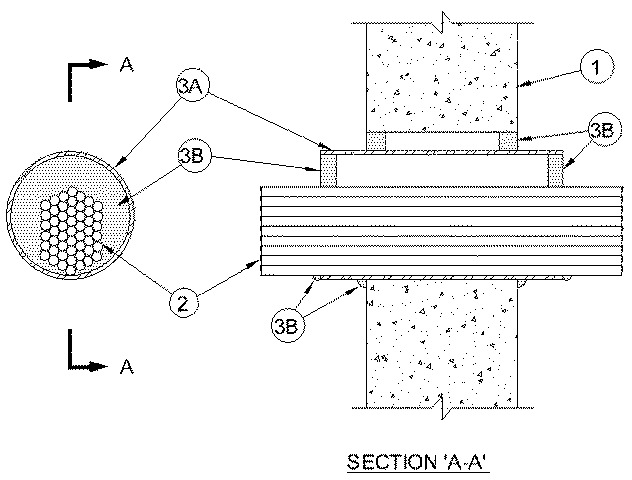

1.Wall Assembly — Min 4-7/8 in. (124 mm) and 6-1/8 in. (156 mm) thick lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete for 1 and 2 hr rated assemblies, respectively. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 5 in. (127 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

The hourly T, FT and FTH Ratings are 1/4 hr and 1/2 hr for 1 and 2 hr rated assemblies, respectively.

2.Cables — Aggregate cross-sectional area of cables in opening to be max 55.6 percent of the cross-sectional area of the opening. Cables to be bundled together and rigidly supported on both sides of wall assembly. The annular space between cable bundle and edge of metallic sleeve (Item 3A) shall be min 0 in. to max 1/8 in. (3.2 mm). The following types and sizes of cables may be used:

A.Max 4/C No. 12 AWG (or smaller) cable with PVC insulation and jacket. B.Max 1/C No. 350 MCM cable with XLPE insulation and jacket. C.Max No. 18 AWG RG6/U coaxial cable with PVC insulation and jacket. D.Max 62.5/125 micron, Type OFNR, fiber optic cables with PVC insulation and jacket. E.Type RG59/U coaxial cables with polyethylene (PE) insulation and PVC jacket.

3.Firestop System — The firestop system shall consist of the following:

A.Metallic Sleeve — Nom 4 in. (102 mm) diam (or smaller) steel, iron, or EMT sleeve with 0.083 in. (2.1 mm) wall thickness (or thicker), fitted into wall opening with a max annular space of 1/2 in. (13 mm) between the edge of the wall opening. Length of sleeve to be equal to thickness of wall plus 2 in. such that, when installed, the ends of the sleeve project 1 in. (25 mm) beyond each surface of the wall.B.Fill, Void or Cavity Material* - Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, between sleeve and wall opening, flush with wall surfaces. Min 1/2 in. (13 mm) thickness of fill material applied within the annulus between cable bundle and sleeve, flush with ends of sleeve. Fill material to be forced into interstices of cable group to seal any voids on both surfaces of wall. A min 3/8 in. (10 mm) bead of the sealant shall be applied at the point-contact locations of the sleeve with wall and cable bundle with sleeve on both sides of the wall assembly.

RECTORSEAL — FlameSafe® FS1900, Metacaulk 1000, Metacaulk 350i, Biostop 350i or Biostop 500+