W-J-2293

August 29, 2016

August 29, 2016

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

- System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

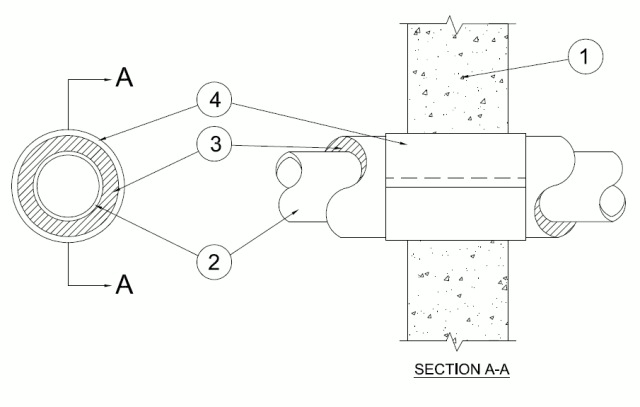

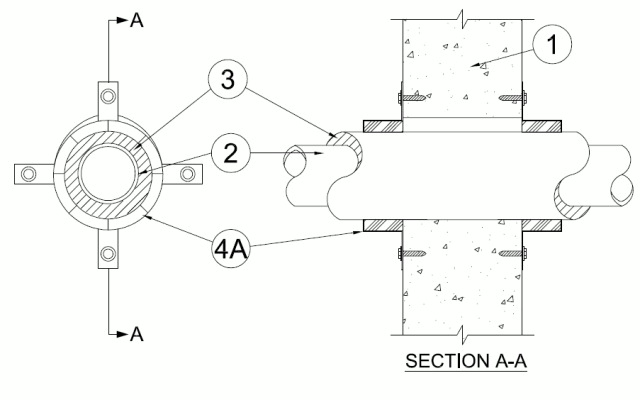

1.Wall Assembly — Min 6 in. (152 mm) thick lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 5 in. (127 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrant — One nonmetallic pipe to be installed either concentrically or eccentrically within the firestop system. Pipe to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipes may be used:

A.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) SDR11 CPVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) FLOWGUARD GOLD® SDR11 CPVC for use in closed (process or supply) or vented (drain, waste or vent) piping systems.

3.Pipe Covering* — Nom 1 in. (25 mm) thick hollow cylindrical heavy density (min 3.5 pcf) glass fiber units jacketed on the outside with an all service jacket. Longitudinal joints sealed with metal fasteners or factory-applied self-sealing lap tape. Transverse joints secured with metal fasteners or with butt tape supplied with the product. The annular space shall be min 0 in. (point contact) to max 5/8 in. (16 mm).

See Pipe and Equipment Covering - Materials (BRGU) category in the Building Materials Directory for names of manufacturers. Any pipe covering material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

4.Firestop System — The firestop system shall consist of the following:

Configuration A

A.Firestop Device — Galv steel sleeve lined with an intumescent material sized to fit the outer diam of the insulated through penetrant. Device to be installed in accordance with the manufacturer's installation instructions along with the following: Device to be wrapped around outer circumference of insulated through penetrant and installed through the annular space and friction fit within the opening. The device shall be centered within the wall and extend equally beyond each surface of the wall.

RECTORSEAL — FlameSafe® Intumescent Sleeve 234, Metacaulk Intumescent Sleeve 234 or Biostop Intumescent Sleeve 234

Configuration B A.Firestop Device* — Galv steel collar lined with an intumescent material sized to fit outer diam of the insulated through penetrant. Device to be installed around insulated through penetrant in accordance with accompanying installation instructions. Device incorporates anchor tabs for securement to both surfaces of the wall by means of min 3/16 in. (5 mm) diam steel hollow wall anchors or min 3/16 in. (5 mm) by 1-1/4 in. (32 mm) concrete anchor screws.

RECTORSEAL — Metacaulk Pipe Collar, Biostop Pipe Collar or Flamesafe Pipe CollarA1.Fill, Void or Cavity Material* — Wrap Strip — As an alternate to Item 4A, two layers of nom 1/4 in. (6 mm) thick by 1 in. (25 mm) wide intumescent wrap strip wrapped around the outer circumference of the insulated pipe on each side of the wall. Wrap strip installed with butted seam and such that edge of wrap strip is flush with the surface of wall. Wrap strip temporarily secured with tape or tie wire.

RECTORSEAL — Metacaulk Wrap Strip, Biostop Wrap Strip or Flamesafe Wrap StripC.Steel Collar — When Item 4A1 is used, a collar fabricated from coils of precut min 0.016 in. thick (0.41 mm) galv steel available from fill material manufacturer shall be installed to retain wrap strip. Collar shall be nom 1 in. (25 mm) deep with 1 in. (25 mm) wide by 1-1/2 in. (38 mm) long anchor tabs for attachment to wall. In addition, collar provided with 1/2 in. (13 mm) wide by 3/4 in. (19 mm) long retainer tabs opposite the anchor tabs. Collar shall be wrapped over the wrap strip, overlapping min 1 in. (25 mm). The retainer tabs are folded 90 deg towards the pipe to maintain the annular space around the pipe and to retain the wrap strip. Collars secured to wall at each anchor tab with 1/4 in. (6 mm) diam by min 1-1/4 in. (32 mm) long concrete anchors in conjunction with 1/4 by 5/8 in. (6 by 16 mm) diam steel washers.