W-J-2178

May 20, 2014

May 20, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

System tested with a pressure differential of 50 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

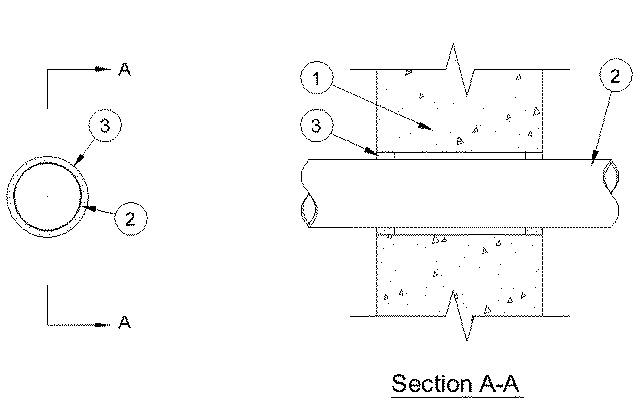

1.Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 3 in. (76 mm).

2.Through Penetrant — One nonmetallic pipe or conduit to be installed either concentrically or eccentrically within the firestop system. Pipe or conduit to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipes or conduit may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) PS 100 PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping system. The annular space shall be min 1/4 in. (6 mm) to max 3/4 in. (19 mm). The T and FTH Ratings are 2 hr for PS 100 PVC pipe.B.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) SDR 13.5 CPVC pipe for use in closed (process or supply) piping system. The annular space shall be min 1/4 in. (6 mm) to max 3/4 in. (19 mm). The T and FTH Ratings are 2 hr for SDR 13.5 CPVC pipe.C.Rigid Electrical Nonmetallic Conduit (RNMC) — Nom 2 in. (51 mm) (or smaller) PVC conduit installed in accordance with the National Electrical Code (NFPA 70). The annular space shall be min 1/4 in. (6 mm) to max 3/4 in. (19 mm). The T and FTH Ratings are 2 hr for RNMC PVC conduit.D.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping system. The annular space for Schedule 40 PVC pipe shall be min 0 in. (point contact) to max 3/4 in. (19 mm). The T and FTH Ratings are 1-3/4 hr for Schedule 40 PVC pipe.

3.Fill, Void or Cavity Material* - Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush with both surfaces of wall. At point contact location between Schedule 40 PVC pipe and concrete, a min 1/2 in. (13 mm) diam bead of fill material shall be applied at pipe/concrete interface on both sides of wall.

RECTORSEAL — Metacaulk 1000 or Metacaulk 350i