W-J-2162

May 20, 2014

May 20, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

- System tested with a pressure differential of 50 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

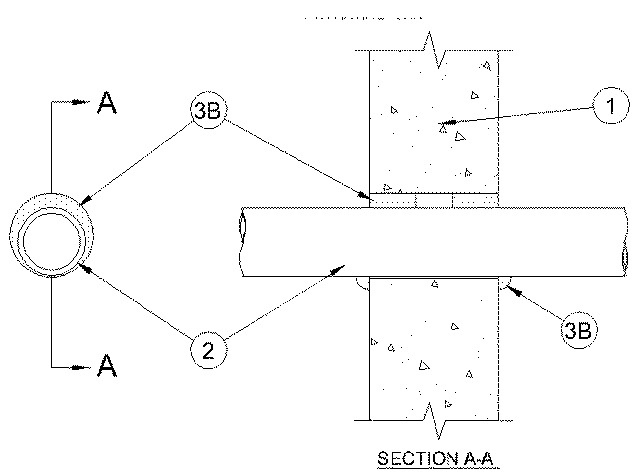

1.Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 2-3/8 in. (60 mm).

2.Nonmetallic Pipe — One non-metallic pipe or tubing to be installed either concentrically or eccentrically within the firestop system. The annular space shall be min 0 in. (point contact) to max 1/2 in. (13 mm). Pipe or tubing to be rigidly supported on both sides of wall assembly. The following types and sizes of non-metallic pipes or tubing may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 1-1/2 in. (38 mm) diam (or smaller) Schedule 40 solid core or cellular core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Electrical Non-Metallic Tubing (ENT) — Nom 1-1/2 in. (38 mm) (or smaller) PVC tubing installed in accordance with the National Electrical Code (NFPA 70).C.Cross Linked Polyethylene (PEX) Tubing — Nom 1 in. (25 mm) (or smaller) PEX tubing installed in accordance with the National Electrical Code (NFPA 70).

3.Firestop System — The firestop system shall consist of the following:

A.Packing Material — (Optional)— Foam backer rod firmly packed into opening as a permanent form. Packing material to be recessed from each surface of the wall to accommodate the required thickness of fill material.B.Fill Void or Cavity Materials* — Caulk — Min 5/8 in. (16 mm) thickness of fill material applied within the annulus on both surfaces of the wall assembly. A min 1/2 in. (13 mm) diam bead of caulk shall be applied to the pipe/gypsum board interface at the point contact location on both sides of wall.

RECTORSEAL — Metacaulk 1000 or Metacaulk 350i