W-J-2094

March 13, 2017

March 13, 2017

F Rating — 2 Hr

T Rating — 2 Hr

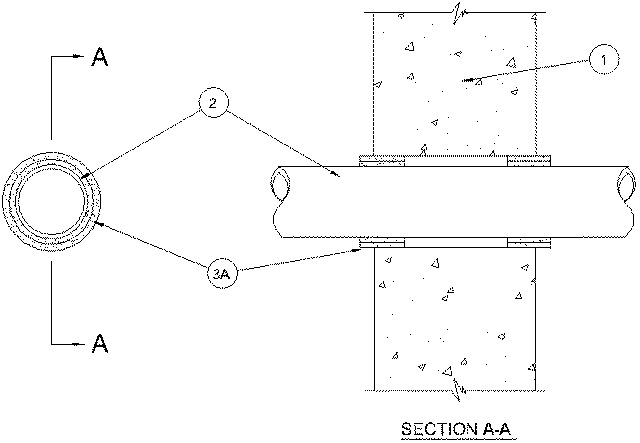

1.Wall Assembly — Min 6 in. thick lightweight or normal weight (100-150 pcf) concrete wall assembly. Wall may also be constructed of any UL ClassifiedConcrete Blocks* . Max diam of opening is 5-1/2 in.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — One nonmetallic pipe to be centered within the firestop system. A nom annular space of 1/2 in. is required within the firestop system. Pipe to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipes may be used:

A.Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 4 in. diam (or smaller) Schedule 40 cellular or solid core ABS pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Polyvinyl Chloride (PVC) Pipe — Nom 4 in. diam (or smaller) Schedule 40 cellular or solid core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.C.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 4 in. diam (or smaller) SDR 13.5 CPVC pipe for use in closed (process or supply) piping systems.

3.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* - Wrap Strip — Two layers of nom 1/4 in. thick by 2 in. wide intumescent wrap strip individually wrapped around the outer circumference of the pipe and slid into the annular space on each side of wall such that wrap strip extends 3/4 in. beyond each surface of wall. Butted ends in successive layers shall be offset. Wrap strip secured with tape, wire or tie wire.

RECTORSEAL — Metacaulk Wrap Strip