W-J-2092

July 17, 2002

July 17, 2002

F Rating — 2 Hr

T Rating — 2 Hr

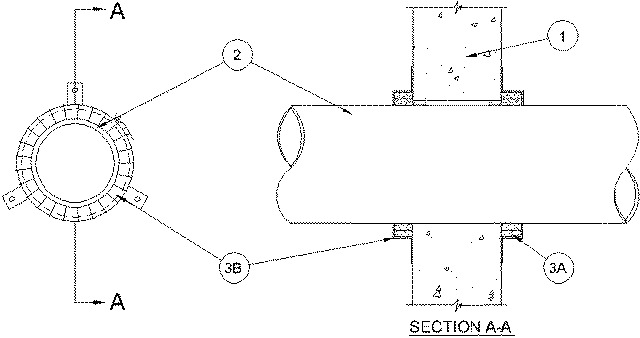

1.Wall Assembly — Min 6 in. thick lightweight or normal weight (100-150 pcf) concrete wall assembly. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 5 in.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — One nonmetallic pipe to be centered within the firestop system. A max annular space of 1/4 in. is required within the firestop system. Pipe to be rigidly supported on both sides of wall assembly. The following types and sizes of nonmetallic pipes may be used:

A.Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 4 in. diam (or smaller) Schedule 40 cellular or solid core ABS pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Polyvinyl Chloride (PVC) Pipe — Nom 4 in. diam (or smaller) Schedule 40 cellular or solid core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.C.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 4 in. diam (or smaller) SDR 13.5 CPVC pipe for use in closed (process or supply) piping systems.

3.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* - Wrap Strip — Two layers of nom 1/4 in. thick by 2 in. wide intumescent wrap strip individually wrapped around the outer circumference of the pipe. Butted ends in successive layers shall be offset. Wrap strip butted tightly against both surfaces of wall. Wrap strip secured with tape, wire or tie wire.

RECTORSEAL — Metacaulk Wrap StripB.Steel Collar — Collar fabricated from coils of precut min 0.016 in. thick (No. 28 gauge) galv steel available from fill material manufacturer. Collar shall be nom 2 in. deep with 1 in. wide by 1-1/2 in. long anchor tabs on 4 in. centers for securement to both surfaces of wall. In addition, collars contain retainer tabs 1/2 in. wide by 3/4 in. long, located opposite the anchor tabs. Collar shall be wrapped over the wrap strip, overlapping min 1 in. At the overlap, the two ends of the collar shall be transversely slit from opposite directions for a distance of 1-1/2 in., approximately 1/2 in. from the ends, and tucked together. The retainer tabs are folded 90 deg towards the pipe to maintain the annular space around the pipe and to retain the wrap strip. Collar secured to both surfaces of wall at each anchor tab by means of 1/4 in. diam by 1-1/2 in. long steel expansion bolts steel or Tapcon® concrete anchors in conjunction with 1/4 in. by 5/8 in. diam washers.