W-J-2035

March 13, 2017

March 13, 2017

F Rating — 2 Hr

T Rating — 0 Hr

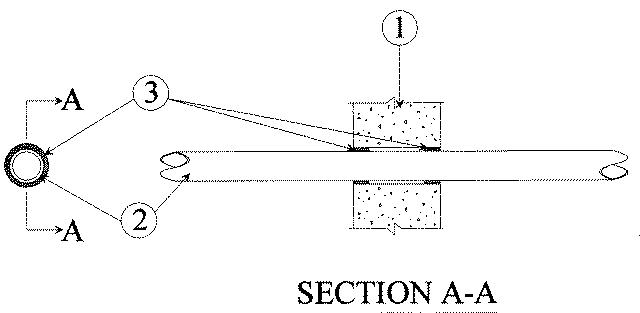

1.Wall Assembly — Min 5 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 3 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrant — One nonmetallic pipe or tube to be centered within the firestop system with a nom 5/16 in. annular space. Pipe or tube to be rigidly supported on both sides of wall assembly. The following types and sizes of pipes may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. diam (or smaller) Schedule 40 cellular or solid core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 2 in. diam (or smaller) Schedule 40 cellular or solid core ABS pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.C.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. diam (or smaller) SDR 17 CPVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.D.Crosslinked Polyethylene (PEX) Tubing — Nom 1 in. diam (or smaller) SDR 9 PEX tube for use in closed (process or supply) piping systems.

3.Fill, Void or Cavity Material* — Wrap Strip — Nom 1/4 in. thick by 1 in. wide intumescent wrap strip. The wrap strip is continuously wrapped around the outer circumference of the pipe once and slid into annular space such that the ends are flush with the surface of the wall. Wrap strips are installed on each surface of the wall.

RECTORSEAL — Metacaulk Wrap Strip