W-J-1087

February 4, 2014

February 4, 2014

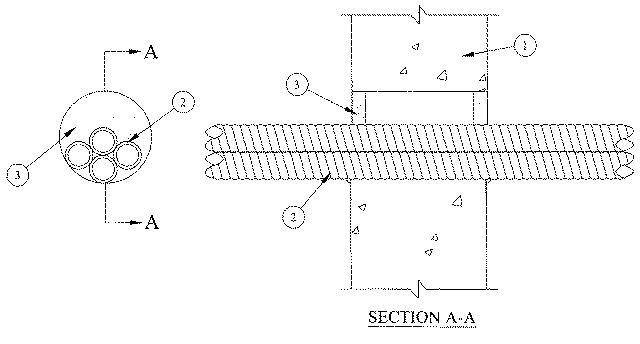

1.Wall Assembly — Min 6 in. (152 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 4 in. (102 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — A max of four nom 1 in. (25 mm) diam (or smaller) flexible aluminum tubing to be installed within the opening. The space between the through penetrants shall be a min of 0 in. (point contact) to a max of 1/4 in. (6 mm). The annular space between the through penetrants and periphery of opening shall be min 0 in. (point contact) to max 1-1/2 in. (38 mm). Tubing to be rigidly supported on both sides of wall assembly.

3.Fill, Void or Cavity Material* — Sealant — Min 5/8 in. (16 mm) thickness of fill material applied within annulus, flush with both surfaces of wall. At the point contact location between through penetrant and concrete, a min 3/8 in. (10 mm) diam bead of fill material shall be applied at the concrete/through penetrant interface on both surfaces of wall. Additional sealant shall be forced into interstices of through penetrants to max extent possible.

RECTORSEAL — FlameSafe FS1900, FS1901, FS1905, FS1929, Metacaulk 1000, Metacaulk 350i, Biostop 350i or Biostop 500+