W-J-1019

November 29, 1995

November 29, 1995

F Rating — 2 Hr

T Rating — 1-1/2 Hr

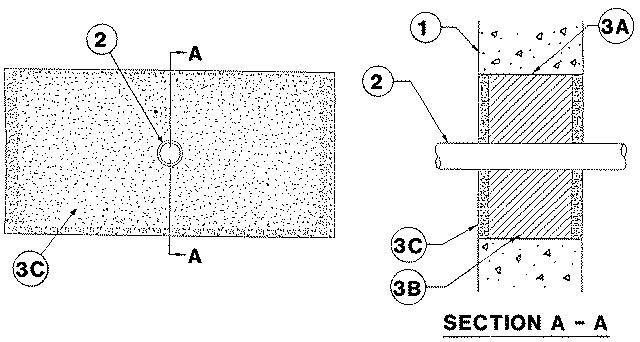

1.Wall Assembly — Min 5 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is 128 sq in. with max dimension of 16 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Metallic Pipe — Nom 1 in. diam (or smaller) steel electrical metallic tubing or steel conduit. One conduit to be centered within the firestop system. Min spacing between conduit and outside perimeter of opening to be 3-1/2 in. Conduit to be rigidly supported on both sides of wall assembly.

3.Firestop System — The firestop system shall consist of the following:

A.Steel Wire Mesh — Rectangular sleeve fabricated from No. 8 steel wire mesh having a min 1 in. lap along the longitudinal seam. Length of steel wire mesh to be 4-3/4 in., centered and formed to fit periphery of through opening.B.Packing Material — Min 4.0 in. thickness of min 3.5 pcf mineral wool batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from both surfaces of wall as required to accommodate the required thickness of fill material.C.Fill, Void or Cavity Material* — Caulk — Min 1/2 in. thickness of fill material applied within the annulus, flush with both surfaces of wall.

RECTORSEAL — Metacaulk 950