F-C-2192

November 14, 2013

November 14, 2013

F Rating — 1 Hr

T Rating — 3/4 Hr

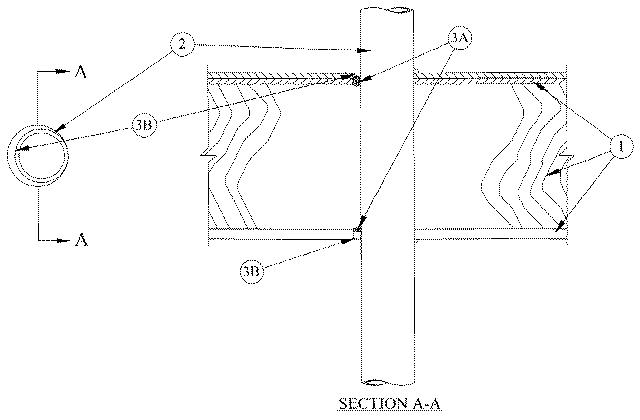

1.Floor-Ceiling Assembly — The 1 hr fire-rated wood joist floor-ceiling assembly shall be constructed of the materials and in the manner specified in the individual L500 Designs in the UL Fire Resistance Directory, as summarized below:

A.Flooring System — Lumber or plywood subfloor with finish floor of lumber, plywood or Floor Topping Mixture* as specified in the individual Floor-Ceiling Design. Max diam of floor opening is 3-1/4 in.B.Wood Joists — Nom 10 in. deep (or deeper) lumber, steel or combination lumber and steel joists, trusses or Structural Wood Members* with bridging as required and with ends firestopped.C.Gypsum Board * — Nom 5/8 in. thick as specified in the individual Floor-Ceiling Design. Gypsum board secured to joists as specified in the individual Floor-Ceiling Design. Max diam of opening is 3-1/4 in.

2.Through Penetrants — One nonmetallic pipe to be installed either concentrically or eccentrically within the firestop system. Diam of the circular opening in flooring, and top and sole plates of chase wall is 5/8 or 7/8 in. larger than the actual diam of the pipe such that the annular space is min 0 in. (point contact) to max 7/8 in. Pipe to be rigidly supported on both sides of floor-ceiling assembly. The following types and sizes of nonmetallic pipes may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. diam (or smaller) Schedule 40 cellular or solid core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping system.B.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. diam (or smaller) SDR17 CPVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.C.Rigid Nonmetallic Conduit+ — Nom 2 in. diam (or smaller) Schedule 40 PVC conduit installed in accordance with Article 347 of the National Electrical Code, (NFPA No. 70).D.Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 1-1/2 in. diam Schedule 40 cellular or solid core ABS pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.E.Crosslinked Polyethylene (PEX) Tubing — Nom 1 in. (25 mm) diam (or smaller) SDR 9 PEX tubing for use in closed (process or supply) or vented (drain, waste or vent) piping systems.F.Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene Composite Pressure Pipe (PEX-AL-PEX) — Nom 1 in. diam (or smaller) PEX-AL-PEX pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.

3.Firestop System — The firestop system shall consist of the following:

A.Packing Material — Foam backer rod firmly packed into opening as a permanent form. Packing material to be recessed from top surface of subfloor as required to accommodate the required thickness of fill material. When MC150+ fill material is used, no packing material is required.B.Fill, Void or Cavity Material* — Caulk — Min 1/4 in. thickness of Metacualk 1000 or 3/4 in. thickness of MC150+ fill material applied within annulus, flush with top surface of subfloor. At point contact location, a min 1/4 in. diam bead of fill material shall be applied to the penetrant/plywood interface on top surface of floor assembly. Min 1/2 in. thickness of Metacaulk 1000 or 5/8 in. thickness of MC150+ applied within annulus, flush with bottom surface of ceiling. At point contact location, a min 1/4 in. diam bead of fill material shall be applied to the penetrant/gypsum board interface on bottom surface of ceiling. ABS pipe (item 2D) is limited for use with Metacaulk 1000 only.

RECTORSEAL — Metacaulk 1000 or MC150+