F-C-2087

July 15, 2014

July 15, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

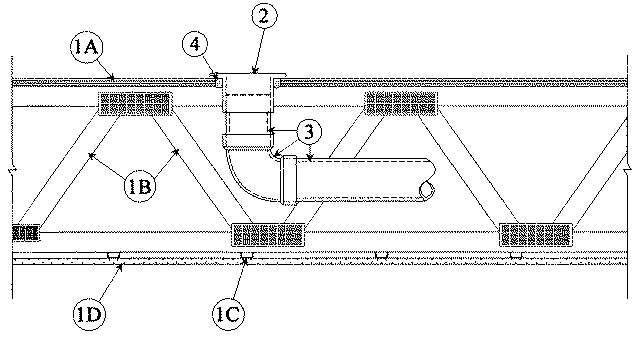

1.Floor-Ceiling Assembly — The 1 hr fire-rated solid or trussed lumber joist floor-ceiling assembly shall be constructed of the materials and in the manner specified in individual L500 Series Floor-Ceiling Designs in the UL Fire Resistance Directory, as summarized below:

A.Flooring System — Lumber or plywood subfloor with finish floor of lumber, plywood or Floor Topping Mixture* as specified in the individual Floor-Ceiling Design. Max diam of opening is 5 in. (127 mm).B.Wood Joists — Nom 2 by 10 in. (51 by 254 mm) lumber joists spaced 16 in. (406 mm) OC with nom 1 by 3 in. (25 by 76 mm) lumber bridging and with ends firestopped. As an alternate to lumber joists, nom 10 in. (254 mm) deep (or deeper) lumber, steel or combination lumber and steel joists trusses or Structural Wood Members* with bridging as required with ends firestopped.C.Furring Channels — (Not Shown) — Resilient galv steel furring installed perpendicular to wood joists (Item 1B) between gypsum board (Item 1D) and wood joists as required in the individual Floor-Ceiling Design.D.Gypsum Board* — Nom 4 ft (1.2 m) wide by 5/8 in. (16 mm) thick as specified in the individual Floor-Ceiling Design. Gypsum board secured to wood joists as specified in the individual Floor-Ceiling Design.

2.Closet Flange — Polyvinyl chloride (PVC) or acrylonitrile butadiene styrene (ABS) closet flange installed in hole-sawed opening in flooring system with flange secured to top of flooring with steel screws. Diam of circular opening through flooring (Item 1A) to be max 1/2 in. (13 mm) larger than outside diam of closet flange.

3.Drain Piping — Nom 4 in. (102 mm) diam (or smaller) Schedule 40 PVC or ABS drain piping and fittings. Short length of pipe with 90 degree elbow fitting cemented into bottom socket of closet flange. Drain piping to soil stack cemented into elbow.

4.Fill, Void or Cavity Material* — Sealant — Fill material forced into annulus between closet stub and periphery opening in flooring to max extent possible, flush with bottom surface of floor. Additional fill material to be installed such that a min 3/8 in. (10 mm) crown is formed around the closet stub on bottom surface of floor.

RECTORSEAL — FlameSafe FS1900, FS1901, FS1905, FS1929, FS900+, Metacaulk MC 150+, Metacaulk 1000, Metacaulk 350i, Biostop BF 150+, Biostop 350i or Biostop 500+

5.Water Closet — (Not Shown) — Floor mounted vitreous china water closet.