December 4, 2018

| ANSI/UL 1479 (ASTM E814) |

|---|

| F Rating — 2 Hr |

| T Rating — 0 Hr |

| L Rating At Ambient — Less Than 1 CFM/device (See Item 5 and 6) |

| L Rating At 400 F — Less Than 1 CFM/device (See Item 5 and 6) |

| W Rating — Class 1 (See Item 5 and 6) |

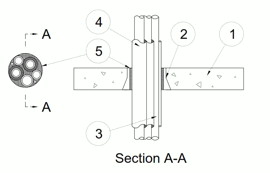

1.Floor Assembly — (Config A) Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.

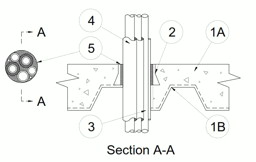

1A.Floor Assembly — (Config B) As an alternate to item 1. The fire-rated unprotected concrete and steel floor assembly shall be constructed of the materials and in the manner specified in the individual D900 Series designs in the UL Fire Resistance Directory and as summarized below:

A.Concrete — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.B.Steel Floor and Form Units — Composite or non-composite max 3 in. (76 mm) deep fluted galv units as specified in the individual Floor-Ceiling design.

2.Firestop Device* — Cast in place firestop device permanently embedded during concrete placement in accordance with accompanying installation instructions. The device may project up to a max of 5-1/2 in. (140 mm) or 3-1/2 in. (89 mm) above top surface of floor or trimmed flush with top surface of floor in min 2-1/2 in. (64 mm) or 4-1/2 in. (114 mm) thick floors, respectively. The devices are provided in a nom 2 in. (51 mm), 3 in. (76 mm), 4 in. (102 mm) and 6 in. (152 mm) size.

RECTORSEAL — Metacaulk Cast-in-Place Device

3.Through Penetrants — Pipes, tubing or cable to be bundled within the opening. The space between penetrants and periphery of opening and annular space between penetrants shall be min 0 in. (point contact). Penetrants to be rigidly supported on both sides of floor assembly. The following types and sizes of penetrants may be used:

A.Metallic Pipes — A max of six pipes or tubes installed within opening. The following types and sizes of metallic pipes, conduits or tubing may be used:

a.Copper Tubing — Nom 1-1/2 in. (38 mm) diam (or smaller) Type L (or heavier) copper tubing.b.Copper Pipe — Nom 1-1/2 in. (38 mm) diam (or smaller) Regular (or heavier) copper pipe.c.Steel Pipe — Nom 1-1/2 in. (38 mm) diam (or smaller) schedule 40 or heavier steel pipe.d.Conduit — Nom 1-1/2in. (38 mm) diam (or smaller) steel electric metallic tubing (EMT) or nom 1-1/2 in. (38 mm) diam (or smaller) rigid steel conduit.B.Cables — A max of two, max 8/C No. 18 AWG (or smaller) thermostat cables; XLPE or PVC insulation with XLPE or PVC jacket.

4.Pipe Coverings* — All tubing greater than nom 1 in. (25 mm) diam shall be provided with one of the following pipe coverings.

A.Tube Insulation-Plastics+ — Max 1 in. (25 mm) thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished In the form of tubing. Tubing may or may not be provided on all or any copper tubes or pipes.See Plastics (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and having a UL 94 Flammability Classification of 94-5A may be used.

B.Pipe and Equipment Covering Materials* — Nom 1 in. (25 mm) thick hollow cylindrical heavy density glass fiber units jacketed on the outside with an all service jacket. Longitudinal joints sealed with metal fasteners or factory-applied self-sealing lap tape. Transverse joints secured with metal fasteners or with butt tape supplied with the product.See Pipe and Equipment Covering - Materials* (BRGU) category in the Building Materials Directory for names of manufacturers. Any pipe covering material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

5.Packing Material — Min 4 in. (102 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into the annular space as a permanent form. The packing material is to be installed flush with the top surface of the floor.

6.Fill, Void or Cavity Material* — Caulk — (Optional, Not Shown) - Min 1/2 in. (13 mm) thickness. Caulk applied within device to finish flush with top surface of device.

RECTORSEAL — Metacaulk 150+,Metacaulk 1000 or Metacaulk 1200W Rating and L Ratings apply only when packing material (Item 5) and (Item 6) sealant is used.

+Bearing the UL Recognized Component Mark