F-A-3030

December 4, 2018

December 4, 2018

| ANSI/UL 1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

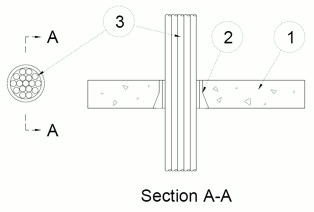

1.Floor Assembly — Min 2-1/2 in. (64 mm) or min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.The F Rating of the firestop system is 2 and 3 Hr for min 2-1/2 in. (64 mm) and min 4-1/2 in. (114 mm) thick concrete, respectively. The T Rating of the firestop system is 0 and 3/4 Hr for min 2-1/2 in. (64 mm) and min 4-1/2 in. (114 mm) thick concrete, respectively.

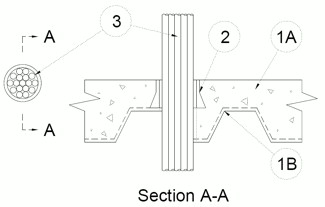

1A.Floor Assembly — (Not shown) As an alternate to item 1, The fire-rated unprotected concrete and steel deck floor assembly shall be constructed of the materials and in the manner specified in the individual D900 Series designs in the UL Fire Resistance Directory and as summarized below:

A.Concrete — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.B.Steel Floor and Form Units* — Composite or non-composite max 3 in. (76 mm) deep fluted galv units as specified in the individual Floor-Ceiling design.

2.Firestop Device* — Cast in place firestop device permanently embedded during concrete placement in accordance with accompanying installation instructions. The device may project up to a max of 3-1/2 in. above top surface of floor or trimmed flush with top surface of floor in min 4-1/2 in. (114 mm) floors. The device may project up to a max of 5-1/2 in. (140 mm) above top surface of min 2-1/2 in. (64 mm) floors. The devices are provided in nom 2, 3, 4 and 6 in. (51,76,102 and 152 mm) diam sizes.

RECTORSEAL — Metacaulk Cast-in-Place Device

3.Cables — Maximum bundle size is matched to the device size and minimum bundle diameter is 1 in. (25.4 mm) less than nominal device size. (Item 2). The bundle diameter shall not exceed 6 in. (152 mm). Annular space between cables and periphery of device or sleeve shall not exceed 1/2 in.(13 mm). Cables to be rigidly supported on both sides of floor assembly. Any combination of the following types and sizes of cable may be used:

A.Max 300 pair No. 22 AWG (or smaller) copper conductor with polyvinyl chloride (PVC) insulation and jacketing material. B.Max 1/C No. 4/0 AWG (or smaller) copper conductor cable with cross-linked polyethylene (XLPE) or PVC jacket. C.Max 7/C No. 12 AWG (or smaller) copper conductor power and control cables with XLPE or PVC insulation with XLPE or PVC jacket. D.Max 3/C No. 3/0 AWG (or smaller) copper or aluminum conductor SER cables with PVC insulation and jacket. E.Max 3/C No. 2/0 AWG (or smaller) copper conductor PVC jacketed aluminum clad or steel clad TECK 90 cable. F.Max 110/125 fiber optic (F.O.) cable with PVC insulation and jacket. G.Max 3/C with ground No. 8 AWG (or smaller) copper conductor NM cable with PVC insulation and jacket. H.RG/U coaxial cable with fluorinated ethylene (FE) or PVC insulation and jacket. I.Max 4 pair No. 24 AWG (or smaller) copper conductor data cable with Hylar jacket and insulation. J.Max three conductor No. 12 AWG (or smaller) MC (BX) copper cable with polyvinyl chloride insulation and jacket materials. K.Through Penetrating Product*-Any cables, Armored Cable+ or Metal Clad Cable+ currently Classified under the Through Penetrating Product category.

See Through Penetrating Product (XHLY) category in the Fire Resistance Directory for names of manufacturers

4.Packing Material — (Optional, Not Shown) Min 3 in. (76 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into the annular space as a permanent form. The packing material is to be installed flush with the top surface of the floor in min 4-1/2 in. (114 mm) floor. In min 2-1/2 in. (64 mm) floor, the firestop device (Item 2) shall extend a min 2 in. (51 mm) above the top surface of floor and the packing material is to be recessed 1-1/2 in. (38 mm) below the top surface of the floor and extend upward, a min of 1-1/2 in. (38 mm) above the top surface of the floor.

5.Fill, Void or Cavity Material* — Caulk — (Optional, Not Shown) - Min 1/2 in. (13 mm) thickness Caulk applied within device to finish flush with top surface of device.

RECTORSEAL — Metacaulk 150+, Metacaulk 1000 or Metacaulk 1200W Rating and L Ratings apply only when packing material (Item 4), and (Item 5) sealant is used.