F-A-2269

April 15, 2022

April 15, 2022

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

|

F Ratings — 3 Hr |

F Ratings — 3 Hr ) |

System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

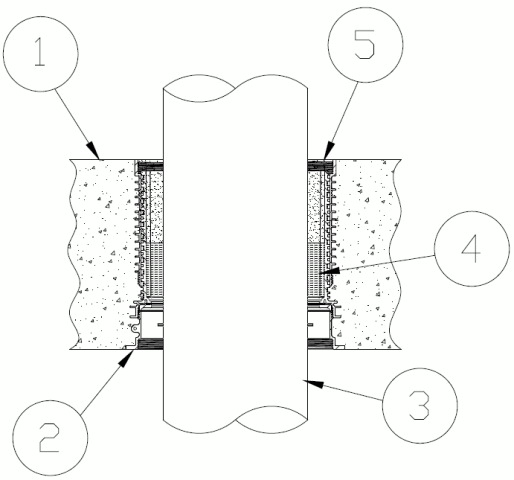

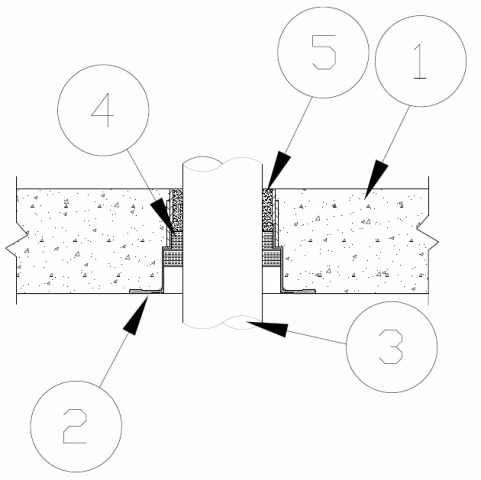

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete measured over top of device base.

1A.Floor Assembly — (As an alternate to Item 1) The fire-rated concrete and fluted steel deck floor assembly shall be constructed of the materials and in the manner specified in the individual D900 Series designs in the UL Fire Resistance Directory and as summarized below:A.Concrete — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete topping, as measured over crests of fluted floor units and over top of device base.B.Steel Floor and Form Units* — Composite or noncomposite nom 3 in. (76 mm) deep fluted galv units as specified in the individual Floor-Ceiling design. Diam of opening cut through fluted floor unit to be maximum 1/4 in. (6 mm) larger than outside diameter of bottom extension portion of firestop device base.

2.Firestop Device* — Cast in place firestop device permanently embedded during concrete placement in accordance with accompanying installation instructions. The device shall be installed flush with top and bottom surfaces of floor. For Conf A HFP devices and optional accessories (not shown) includes sleeve extension, deck adapter, water module, aerator adapter midbody seal and/or water dam installed in accordance with installation instructions. The devices are sized to accommodate the nom pipe sizes.

Nom Pipe

Diam in. (mm)Conf A Devices for

Concrete SlabConf A Devices for Fluted

Deck (Not Shown)Conf B Devices for

Concrete SlabConf B Devices for Fluted

Deck (Not Shown)1/4 to 1-1/4 (6 to 32) HFP-H2, HFP-H2B add HFPCD1 WD Sleeve CD Sleeve 1 to 2 (25 to 51) HFP-H3, HFP-H3B add HFPCD2 WD Sleeve CD Sleeve 1-1/4 to 3 (32 to 76) HFP-H4, HFP-H4B add HFPCD3 WD Sleeve CD Sleeve

HOLDRITE — HydroFlame (Config A), HFP-H2 HFP-H2B, HFP-H3, HFP-H3B, HFP-H4, HFP-H4B, (Config B), WD & CD Sleeve

3.Through Penetrant — One nonmetallic pipe or conduit to be installed within the firestop device. Pipe or conduit to be installed in accordance with firestop device installation instructions and rigidly supported on both sides of floor assembly. The following types of pipe, conduit or tubing may be used:A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 solid or cellular core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.A1.Polyvinyl Chloride (PVC) Pipe — As an alternate to Item A, Nom 2 in. (51 mm) diam (or smaller) solid or cellular core Schedule 40 polyvinyl chloride (PVC) pipe.

IPEX INC — System 15 pipingA2.XFR Polyvinyl Chloride (PVC) Pipe — As an alternate to Item A, Nom 2 in. (51 mm) diam (or smaller) IPEX XFR Schedule 40 pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Rigid Nonmetallic Conduit+ — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 PVC conduit installed in accordance with the National Electrical Code (NFPA No. 70).C.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) SDR 13.5 (or heavier) or Schedule 40 CPVC pipe for use in closed (process or supply) piping systems.C1.Chlorinated Polyvinyl Chloride (CPVC) Pipe — As an alternate to Item C, Nom 2 in. (51 mm) diam (or smaller) SDR 11 or 21 CPVC for use in closed (process or supply) piping systems.

IPEX INC — AquaRiseD.Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 solid or cellular core ABS pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.E.Cross-Linked Polyethylene (PEX) Tubing — Nom 2 in. (51 mm) diam (or smaller) SDR 9 PEX tubing for use in closed (process or supply) piping systems. (HFP series devices only) Nom 3 in. (76 mm) diam (or smaller) SDR PEX tubing in closed (process or supply) piping systems.E1.Cross-Linked Polyethylene (PEX) Pipe — As an alternate to Item E, Nom 2 in. (51 mm) diam (or smaller) SharkBite SDR 9 PEX tubing for use in closed (process or supply) piping systems.F.Polypropylene (PP) Pipe — Nom 2 in. (51 mm) diam (or smaller) Aquatherm SDR 7.4 or 11 PP pipe for use in closed (process or supply) piping systems.F1.Polypropylene PP-RCT Pipe — As an alternate to Item F, Nom 2 in. (51 mm) diam (or smaller) Nupi - Niron SDR 7.4 or 11 PP pipe for use in closed (process or supply) piping systems.The T, FT and FTH ratings are 1/2 hr except when Item 3F and 3F1 Polypropylene is used then T, FT and FTH are 0 hr.

4.Packing Material — (Optional) — Min 2 in. (102 mm) depth of min 4 pcf (64 kg/m3) mineral wool batt insulation tightly-packed into annular space with its top surface recessed min 2 in. (51 mm) from top surface of floor.

5.Fill, Void or Cavity Material* — Sealant — Min 2 in. (51 mm) thickness of sealant applied within the annulus, flush with the top surface of floor.

RELIANCE WORLDWIDE CORPORATION DBA HOLDRITE HYDROFLAME — HydroFlame 200

+ Bearing the UL Listing Mark