F-A-2237

August 13, 2014

August 13, 2014

F Rating — 2 Hr

T Rating — 2 Hr

- System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

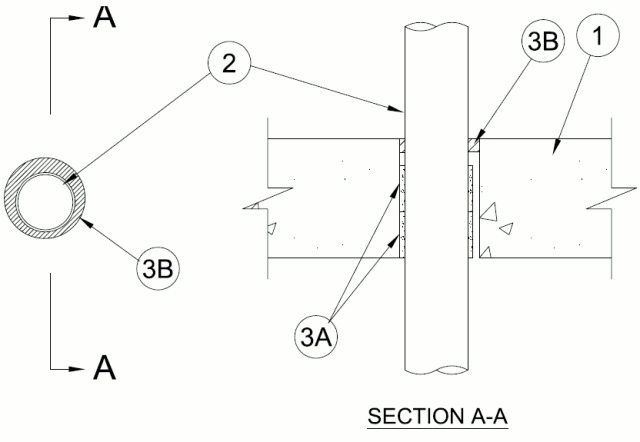

1.Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Max diam of opening is 4 in. (102 mm).

See Concrete Blocks (CAZT) in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — One nonmetallic penetrant installed eccentrically or concentrically within the firestop system. The annular space between pipe and periphery of opening shall be min 1/4 in. (6 mm) to max 1/2 in. (13 mm). Pipe to be rigidly supported on both sides of the floor assembly. The following types and sizes of nonmetallic pipes may be used:

A.Crosslinked polyethylene (PEX) Tubing — Nom 3 in. (76 mm) diam (or smaller) UPONOR - WIRSBO PEX-a SDR 9 tube for use in closed (process or supply) or vented (drain, waste or vent) piping systems.

3.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Materials* — Wrap Strip — One layer of nom 1/4 in. (6 mm) thick by 2 in. (51 mm) wide intumescent elastomeric material faced on one side with a plastic film. Wrap strip individually wrapped around nonmetallic pipe (film side exposed) and slid into annular space with ends butted and held in place with tape. Wrap strip to be double stacked. Bottom edge of wrap strip flush with bottom of surface of floor.

RECTORSEAL — Metacaulk Wrap Strip, Biostop Wrap Strip or Flamesafe Wrap Strip

B.Fill, Void or Cavity Material* — Caulk — Min 1/2 in. (13 mm) thickness of sealant applied within the annulus, flush with top surface of floor.

RECTORSEAL — Metacaulk 1000, Biostop 500+, FlameSafe 1900