F-A-2211

October 24, 2019

October 24, 2019

F Rating -3 Hr

T Rating - 1-1/2 Hr

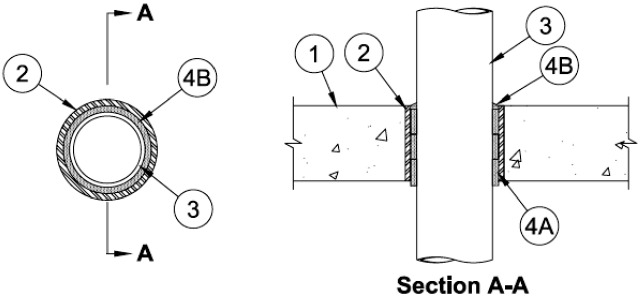

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Max diam of opening is 5 in. (127 mm).

2.Steel Sleeve — (Optional) - Max 5 in. (127 mm) Schedule 10 (or heavier) steel sleeve, cast or grouted into opening, flush with both sides of the floor assembly.

3.Through Penetrants — Nom 4 in. (102 mm) diam (or smaller) nonmetallic pipe or conduit installed within the firestop system. A min 1/4 in. (6 mm) annular space shall be maintained between the penetrant and the sleeve or the periphery of the opening. Pipe or conduit to be rigidly supported on both sides of floor assembly. The following types of metallic pipes or conduits may be used:

A.Polyvinyl Chloride (PVC) Pipe — Schedule 40 solid core PVC or cellular core PVC (ccPVC) pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Rigid Nonmetallic Conduit (RNC)+ — Schedule 40 PVC conduit installed in accordance with the National Electrical Code (NFPA No. 70).C.Chlorinated Polyvinyl Chloride (CPVC) Pipe — SDR13.5 CPVC pipe for use in closed (process or supply) piping systems.

4.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* - Wrap Strip — Nom 1/4 in. (6 mm) thick intumescent material faced on both sides with a plastic film, supplied in 1-1/2 in. (38 mm) wide strips. A stack of three single layers of wrap strip are wrapped around the through-penetrant with butted seams and joints. The butted ends of each single layer are held in place with masking tape. Butted ends in layers of each stack shall be offset. Stacked wrap strips secured together with aluminum foil tape (not shown) around entire circumference with min 1-1/2 in. (38 mm) tape overlap to penetrant at top and bottom of floor opening. The stacked wrap strips are slid into annular space until bottom edge of wrap strip protrudes 1/4 in. (6 mm) below bottom surface of floor.

RECTORSEAL —FlameSafe Wrap Strip B.Fill, Void or Cavity Material* — Sealant — Min 1/2 in. (13 mm) thickness of fill material applied within the annulus, flush with top surface of floor. An additional 1/2 in. (13 mm) fillet of sealant to be built up on top surface of floor to cover steel sleeve and extend a min 1/2 in. (13 mm) up the pipe

RECTORSEAL —FS1900, Metacaulk 150+