F-A-2160

February 8, 2010

February 8, 2010

F Rating — 2 Hr

T Rating — 0 Hr

W Rating — Class 1 (See Item 5)

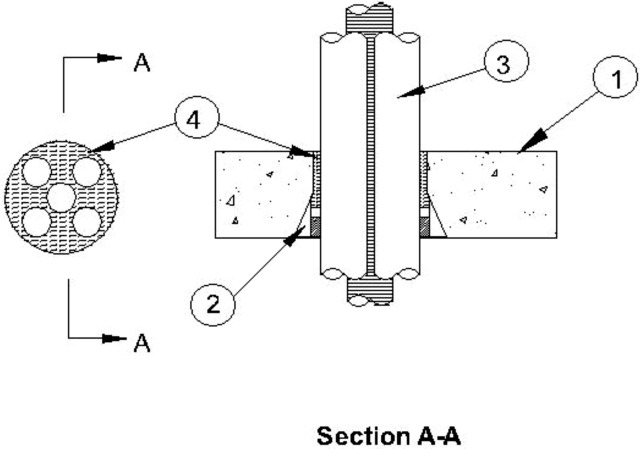

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.

2.Firestop Device* — Cast in place firestop device permanently embedded during concrete placement in accordance with accompanying installation instructions. The device may project up to a max of 3-1/2 in. (89 mm) above top surface of floor or trimmed flush with top surface of floor. The devices are provided in nom 2 in. (51 mm), 4 in. (102 mm) and 6 in. (152 mm).

RECTORSEAL — Biostop or Rectorseal Cast -in- Place Firestop Device

3.Through Penetrants — A max of five nonmetallic pipes, conduit or tube installed eccentrically or concentrically within the firestop system. Annular space between the penetrants and the periphery of the opening shall be min 0 in. (point contact) to max 1 in. (25 mm). Annular space between penetrants is min 1/4 in. (25 mm) to max 1 in. (25 mm). Pipe or conduit to be rigidly supported on both sides of floor assembly. The following types of nonmetallic pipes or conduits may be used:

A.Polyvinyl Chloride (PVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) Schedule 40 solid core PVC pipe for use in closed (process or supply) or vented (drain, waste or vent) piping systems.B.Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 2 in. (51 mm) diam (or smaller) SDR13.5 CPVC pipe for use in closed (process or supply) piping systems.C.Electrical Nonmetallic Tubing (ENT+) — Nom 2 in. (51 mm) diam (or smaller) corrugated-wall electrical nonmetallic tubing (ENT) constructed of polyvinyl chloride (PVC) and installed in accordance with the National Electrical Code (NFPA No. 70).See Electrical Nonmetallic Tubing (FKHU) category in the Electrical Construction Materials Directory for names of manufacturers.

D.Rigid Nonmetallic Conduit (RNC)+ — Nom 1 in. (25 mm) diam (or smaller) Schedule 40 PVC conduit installed in accordance with the National Electrical Code (NFPA 70).

4.Packing Material — A min 4 in. (102 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation shall be firmly packed into the annular space between the penetrant and device as a permanent form. The packing material is to be installed flush with the top surface of the floor or recessed from the top surface of the device to accommodate the required thickness of caulk (Item 5).

5.Fill, Void or Cavity Material* — Caulk — (Optional, Not Shown) - Min 1/4 in. (6 mm) thickness for 2-1/2 in. (64 mm) and 4 in. (102 mm) CIP device and min 3/8 in. (10 mm) thickness for 6 in. (152 mm) CIP device. Caulk applied within device, flush with top surface of device.

RECTORSEAL — Biotherm 100, Biotherm 200SL or Biostop 750 with 2-1/2 in. (64 mm) CIP device only.

W Rating only applies when the optional caulk is used.