F-A-1122

June 24, 2020

June 24, 2020

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

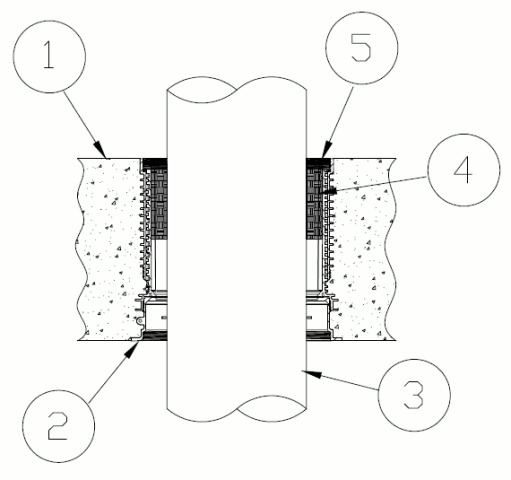

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete measured above the base of the device.

1A.Alternate Floor Assembly — (Optional, Not Shown) — The fire rated unprotected concrete and steel floor assembly shall be constructed of the materials and in the manner specified in the individual D900 Series designs in the UL Fire Resistance Directory and as summarized below:

A.Concrete — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight 100-150 pcf (1600-2400 kg/m3) concrete, measured above the base of the device.B.Steel Floor and Form Units* — Composite or non-composite max 3 in. (76 mm) deep galv steel fluted units as specified in the individual Floor-Ceiling Design.

Configuration A

2.Firestop Device* — Cast in place firestop device permanently embedded during concrete placement or grouted in concrete assembly in accordance with accompanying installation instructions. The device shall be installed flush with top and bottom surfaces of floor. Optional accessories (not shown) includes sleeve extension, water module, water dam, deck adapter, mid body seal and/or aerator adapter installed in accordance with installation instructions.The devices are sized to accommodate the following nom pipe sizes:

Nom Pipe Diam in. (mm) Devices for Concrete Slab Devices for Fluted Deck (Not Shown) 1/4 to 1-1/4 (6 to 32) HFP-H2, HFP-H2B add HFPCD1 1 to 2 (25 to 51) HFP-H3, HFP-H3B add HFPCD2 1-1/4 to 3 (32 to 76) HFP-H4, HFP-H4B add HFPCD3 2-1/2 to 4 (64 to 102) HFP-H5, HFP-H5B add HFPCD4 4 to 5(102 to 127) HFP-H6, HFP-H6B add HFPCD5 5 to 6 (127 to 152) HFP-H7, HFP-H7B add HFPCD6

HOLDRITE —HydroFlame, HFP-Hx, HFP-HxB

3.Through-Penetrant — One metallic pipe, conduit or tubing installed concentrically within the firestop system. The annular space shall be min 1/2 in. (13 mm) to max 2-3/8 in. (60 mm). Pipe, conduit or tubing to be rigidly supported on both sides of floor assembly. The following types of pipe, conduit or tubing may be used:

A.Steel Pipe — Nom 6 in. (152 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe.B.Conduit — Nom 6 in. (152 mm) diam (or smaller) steel electrical metallic tubing (EMT) or steel conduit.C.Copper Tubing — Nom 6 in. (152 mm) diam (or smaller) Type M (or heavier) copper tubing.D.Iron Pipe — Nom 6 in. (152 mm) diam (or smaller) cast or ductile iron pipe.

4.Packing Material — Min 3-3/4 in. (95 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form so that the width of the wool is compressed at least 50 percent. Packing material to be recessed from top surface of floor as required to accommodate the required thickness of fill material.

5.Fill, Void or Cavity Material* — Sealant — Min 1/4 in. (6 mm) thickness of sealant applied within the annulus, flush with the top surface of floor to attain W Rating.

RELIANCE WORLDWIDE CORPORATION DBA HOLDRITE HYDROFLAME —HydroFlame 100, HydroFlame 200, HydroFlame 300SL, HydroFlame 300 CG

6.Pipe Tee Fitting System — (Optional, Not Shown) — For use with Iron Pipe (Item 3D) only. One nom 6 in. (152 mm) diam (or smaller) PVC TESTRITE TEE Fitting (matched to penetrant diameter). The PVC TESTRITE TEE Fitting is secured to metallic penetrant (Item 3D) with compression type pipe coupling elastomeric gasket with stainless steel jacket and stainless steel band clamps for use in vented (drain, waste or vent) iron pipe systems. Installed (Item 3D) penetrant shall extend a minimum of 6 in. (152 mm) above the surface of the floor and minimum 12 in. (302 mm) below the bottom surface of the floor assembly.

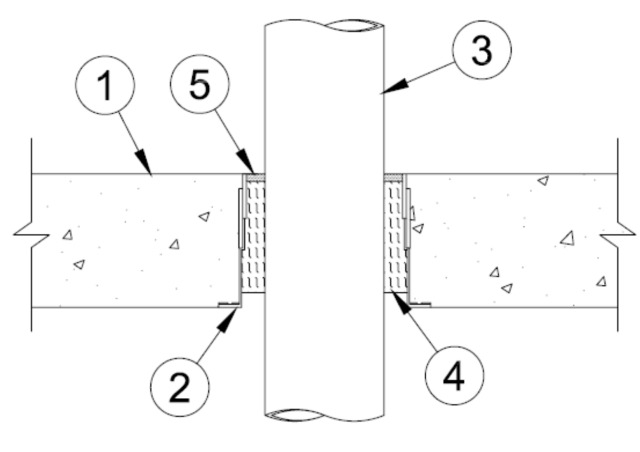

Configuration B

2.Firestop Device* — Max 8 in. (203 mm) diam cast in place firestop device permanently embedded during concrete placement or grouted in concrete in accordance with accompanying installation instructions. The device shall be installed flush with top and bottom surfaces of floor. Optional accessory (not shown) aerator adapter installed in accordance with the installation instructions.

HOLDRITE —HydroFlame WD, CD Sleeve When HydroFlame WD 0600 Sleeve is used, the nominal 1 by 0.3 in. (25 by 7.6 mm) void created by the stepped base within the sleeve shall be tightly-packed with mineral wool batt insulation (Item 4) during firestop installation if concrete floor assembly is less than 7 in. (178 mm) thick.

3.Through-Penetrant — One metallic pipe, conduit or tubing installed concentrically within the firestop system. The annular space shall be min 1/2 in. (13 mm) to max 2-3/8 in. (60 mm). Pipe, conduit or tubing to be rigidly supported on both sides of floor assembly. The following types of pipe, conduit or tubing may be used:

A.Steel Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe.B.Conduit — Nom 4 in. (102 mm) diam (or smaller) steel electrical metallic tubing (EMT) or steel conduit.C.Copper Tubing — Nom 4 in. (102 mm) diam (or smaller) Type M (or heavier) copper tubing.D.Iron Pipe — Nom 6 in. (152 mm) diam (or smaller) cast or ductile iron pipe.

4.Packing Material — Min 3-3/4 in. (95 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form so that the width of the wool is compressed at least 50 percent. Packing material to be recessed from top surface of floor as required to accommodate the required thickness of fill material.

5.Fill, Void or Cavity Material* — Sealant — Min 1/4 in. (6 mm) thickness of sealant applied within the annulus, flush with the top surface of floor. A Min 1/2 in. (13 mm) thickness of sealant applied within the annulus, flush with the top surface of floor to attain W-Rating. Sealant must lap onto top surface of concrete floor around entire perimeter of firestop device to attain W Rating.

RELIANCE WORLDWIDE CORPORATION DBA HOLDRITE HYDROFLAME —HydroFlame 100, HydroFlame 200, HydroFlame 300SL, HydroFlame 300 CG

6.Pipe Tee Fitting System — (Optional, Not Shown) — For use with Iron Pipe (Item 3D) only. One nom 6 in. (152 mm) diam (or smaller) PVC TESTRITE TEE Fitting (matched to penetrant diameter). The PVC TESTRITE TEE Fitting is secured to metallic penetrant (Item 3D) with compression type pipe coupling elastomeric gasket with stainless steel jacket and stainless steel band clamps for use in vented (drain, waste or vent) iron pipe systems. Installed (Item 3D) penetrant shall extend a minimum of 6 in. (152 mm) above the surface of the floor and minimum 12 in. (302 mm) below the bottom surface of the floor assembly.