C-AJ-6012

January 7, 2010

January 7, 2010

F Rating — 2 Hr

T Rating — 0 Hr

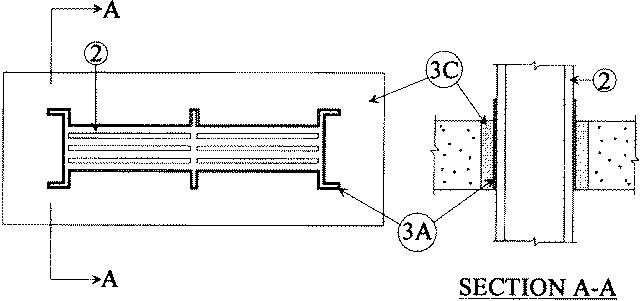

1.Floor or Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is 360 sq. in. with max dimension of 30 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Busway+ — Nom 27 in. wide (or smaller) by 6 in. deep "I" shaped aluminum and steel enclosure containing factory mounted aluminum bars rated for 600 V, 4000 A. One busway to be installed within the opening. The annular space between the flange tip of the busway and the periphery of the opening shall be a nom 2 in. The annular space between the web section of the busway and the periphery of the opening shall be a nom 5-1/4 in. Busway to be rigidly supported on both sides of floor and wall assembly. The busway shall bear the UL Listing Mark and shall be installed in accordance with all provisions of Article 364 of the National Electrical Code, NFPA 70.

3.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Materials* — Putty — Nom 7-1/2 by 6-1/4 in. wide by 1/4 in. thick moldable putty pads installed around the entire perimeter of the busway extending a min 2 in. beyond the top surface of floor and both surfaces of wall assembly.

RECTORSEAL — FSP1077 PuttyB.Forms — (Not Shown) — Used as a form to prevent leakage of fill material installation. Forms to be rigid sheet material, cut to fit the contour of the penetrating item and fastened to the underside of floor or both sides of wall. Forms to be removed after fill material has cured.C.Fill, Void or Cavity Materials* — Mortar — Min 4-1/2 in. thickness of fill material applied flush with top surface of floor and both surfaces of wall. Mortar to be mixed at a rate of 1.1 parts dry mixture to 1.0 part water by weight in accordance with the installation instructions supplied with the product.

RECTORSEAL — Flame Safe Mortar