C-AJ-5251

February 6, 2014

February 6, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

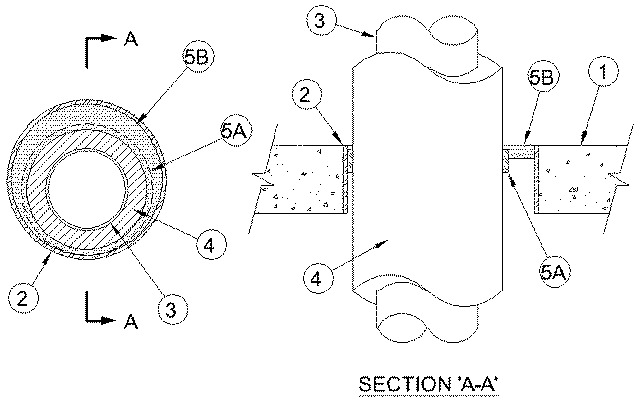

1.Floor or Wall Assembly — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Floor may also be constructed of any min 6 in. thick UL Classified hollow core Precast Concrete Units*. When precast concrete units are used, the max diam of opening is 7 in. (178 mm). Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 10-5/8 in. (270 mm).

See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers.

2.Steel Sleeve - (Optional) — Nom 10 in. (254 mm) diam (or smaller) Schedule 10 (or heavier) steel sleeve cast or grouted into floor or wall assembly, flush with floor or wall surfaces.

3.Through Penetrants — One metallic pipe to be installed either concentrically or eccentrically within the firestop system. Pipe to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of metallic pipes may be used:

A.Steel Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 40 (or heavier) steel pipe.B.Iron Pipe — Nom 4 in. (102 mm) diam (or smaller) cast or ductile iron pipe.C.Copper Tubing — Nom 4 in. (102 mm) diam (or smaller) Type L (or heavier) copper tubing.D.Copper Pipe — Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.

4.Pipe Covering — Nom 2 in. (51 mm) thick hollow cylindrical heavy density (min 3.5 pcf or 56 kg/m3) glass fiber units jacketed on the outside with an all service jacket. Longitudinal joints sealed with metal fasteners or factory-applied self-sealing lap tape. Transverse joints secured with metal fasteners or with butt tape supplied with the product. The annular space between the insulated through penetrant and the periphery of the opening shall be a min of 1/4 in. (6 mm) to a max 2 in. (51 mm).

See Pipe and Equipment Covering-Materials (BRGU) category in the Building Materials Directory for names of manufacturers. Any pipe covering material meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed Index of 50 or less may be used.

5.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Material* — Wrap Strip — Nom 1/4 in. (6mm) thick intumescent material faced on both sides with a plastic film, supplied in 1-1/2 in. (38 mm) wide strips. One layer of wrap strip wrapped around the through-penetrant with the ends butted and held in place with masking tape. The wrap strip shall be recessed a nom 1/4 in. (6 mm) from the top surface of the concrete floor. In walls, and in floors constructed of hollow core precast concrete units, the wrap strip shall be installed on both surfaces of the wall or floor such that the exposed edge of the wrap strip is recessed 1/4 in. (6 mm) from each side of the wall or both surfaces of the floor.

RECTORSEAL — FlameSafe®Wrap Strip, Metacaulk Wrap Strip or Biostop Wrap StripB.Fill, Void or Cavity Material* — Sealant — Min 1/2 in. thickness of fill material applied within the annulus, flush with top surface of floor or with both surfaces of wall assembly. In floors constructed of hollow core precast concrete units, fill material shall be installed symmetrically on both surfaces of floor.

RECTORSEAL — FlameSafe FS1900, Metacaulk 1000, Metacaulk 350i, Biostop 350i or Biostop 500+