C-AJ-5208

February 5, 2014

February 5, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

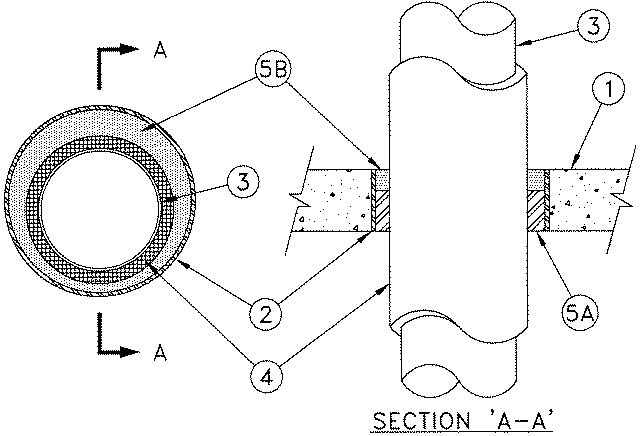

1.Floor or Wall Assembly — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete floor or min 3-1/2 in. (89 mm) thick reinforced lightweight or normal weight concrete wall. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 8-1/4 in. (210 mm).

See Concrete Blocks (CAZT) in Volume 1 of the Fire Resistance Directory for names of manufacturers.

2.Metallic Sleeve (Optional) — Nom 8 in. (203 mm) diam (or smaller) Schedule 10 steel pipe cast or grouted into floor or wall assembly, flush with floor or wall surfaces.

3.Through Penetrants — One metallic pipe or tubing to be installed concentrically or eccentrically within the firestop system. Pipe or tubing to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of metallic pipes or tubing may by used:

A.Steel Pipe — Steel Pipe - Nom 4 in. (102 mm) diam (or smaller) Schedule 5 (or heavier) steel pipe.B.Iron Pipe — Nom 4 in. (102 mm) diam (or smaller) cast or ductile iron pipe.C.Copper Tubing — Nom 4 in. (102 mm) diam (or smaller) Type L (or heavier) copper tubing..D.Copper Pipe — Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.

4.Pipe Insulation — Plastics+ Nom 1 in. thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing. The annular space shall be min 1/2 in. to max 1-3/8 in. Plastics+ Nom 1 in. (25 mm) thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing. The annular space shall be min 1/2 in. (13 mm) to max 1-3/8 in. (35 mm).

See Plastics+ (QMFZ2) category in the Plastic Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and having a UL 94 Flammability Classification 0f 94-5VA may be used.

5.Firestop System — The firestop system shall consist of the following:

A.Packing Material — Min 1-1/2 in. (38 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from top surface of floor or from both surfaces of wall to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* — Sealant Min 1 in. (25 mm) thickness of fill material applied within the annulus, flush with top surface of floor or with both surfaces of wall.

RECTORSEAL — FlameSafe® FS1900, Metacaulk 1000, Metacaulk 350i, Biostop 350i or Biostop 500+

+Bearing the UL Recognized Component Marking