C-AJ-4049

November 30, 1999

November 30, 1999

F Rating — 4 Hr

T Rating — 0 Hr

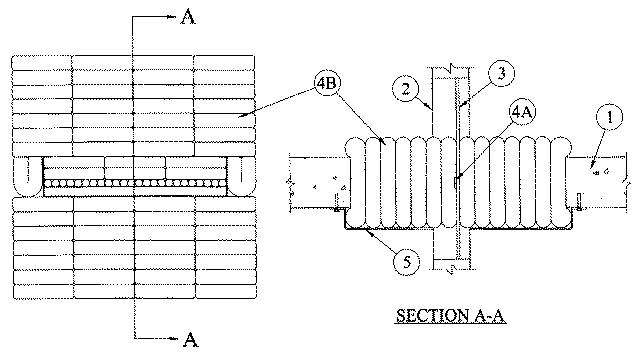

1.Floor or Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is 576 sq in. with max dimension of 24 in.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Cable Tray* — Max 18 in. wide by max 4 in. deep open-ladder cable tray with channel-shaped side rails formed of min 0.057 in. thick aluminum with 1 in. wide rungs spaced 9 in. OC. One cable tray to be centered in opening. The annular space between the cable tray and periphery of opening shall be min 3 in. to max 10 in. Cable trays to be rigidly supported on both sides of floor or wall assembly.

3.Cables — Aggregate cross-sectional area of cables in cable tray to be max 21 percent of the cross-sectional area of the cable tray based on a max 3 in. cable loading depth within the cable tray. Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 25 pr No. 24 AWG telephone cables with polyvinyl chloride (PVC) insulation and jacket. B.Max 4 pr No. 24 AWG telephone cables with PVC insulation and jacket. C.Max 1/C — 350 kcmil (or smaller) cable with PVC insulation and jacket. D.Max 2/C with ground No. 12 AWG Type NM nonmetallic sheathed (Romex) cable with PVC insulation and jacket.

4.Firestop System — The firestop system shall consist of the following:

A.Fill, Void or Cavity Materials* — Caulk — Nom 1/4 in. thick by 1 in. wide strip of caulk applied over both surfaces of cable bundle and overlapping into inside rails of cable tray approx 1/2 in. Caulk strips centered within annular space

RECTORSEAL — Metacaulk 1000B.Fill, Void or Cavity Materials* — Pillows — Max 9 in. long by 6 in. wide by 2 in. thick plastic covered intumescent pillows tightly packed into opening. Pillows tightly packed to fill the annular space between cable tray and periphery of opening. Pillows installed with 9 in. dimension projecting through floor or wall and centered with the opening.

RECTORSEAL — Metacaulk PillowsC.Fill, Void or Cavity Materials* — Caulk — (Not Shown) — After installation of the pillows, min 1/4 in. depth of caulk shall be applied to seal any voids between cables, between cables and the pillows, and between cable tray and pillows on both sides of floor or wall assembly.

RECTORSEAL — Metacaulk 1000

5.Wire Mesh — Nom 2 in. diamond shaped mesh fabricated from min No. 20 AWG galv steel wire. Wire mesh cut to fit the contour of the opening with a min 8 in. lap beyond the periphery of the opening to keep the pillows in place. Wire mesh secured to lower surface of floor assembly with min 1/4 in. diam by 1-1/4 in. long steel expansion bolts or steel Tapcon® concrete anchors in conjunction with min 1/4 in. by 1-1/4 in. diam washers, spaced 12 in. OC. The joints within the wire mesh shall overlap a min of 2 in. and shall be secured together by means of No. 16 AWG steel wire, spaced 6 in. OC.