C-AJ-4027

January 6, 2010

January 6, 2010

F Rating — 3 HR

T Rating — 0 HR

L Rating at Ambient — 2 CFM/sq ft

L Rating at 400 F — 3 CFM/sq ft

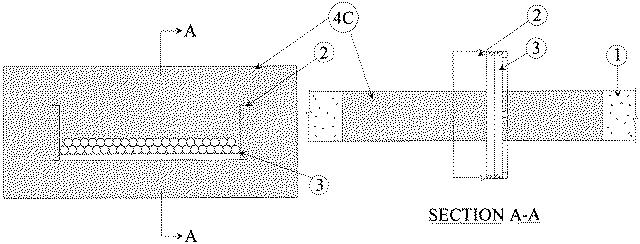

1.Floor or Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is 324 sq in. with max dimensions of 27 in.See Concrete Block (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Cable Tray* — Max 24 in. wide by max 3-1/2 in. deep open ladder cable tray with channel-shaped side rails formed from 0.060 in. (No. 16 MSG) thick steel with 3-1/2 in. by 5/8 in. deep channel shaped rungs spaced 9 in. OC. One cable tray to be centered in the opening. The annular space between the cable tray and the periphery of the opening shall be min 1-1/2 in. to max 4-1/4 in. Cable tray to be rigidly supported on both sides of floor or wall assembly.

3.Cables — Aggregate cross-sectional area of cables in cable tray to be max 20 percent of the cross-sectional area of the cable tray based on a max 2-7/8 in. cable loading depth within the cable tray. Any combination of the following types and sizes of copper conductor cables may be used:

A.Max 1/C - 250 kcmil cable with polyvinyl chloride (PVC)-nylon insulation and PVC jacket. B.Max 3/C - No. 2 AWG cable with PVC-nylon insulation and PVC jacket. C.Max 7/C - No. 12 AWG cable with PVC-nylon insulation and PVC jacket. D.Max 2/C - No. 16 AWG cable with PVC-nylon insulation and PVC jacket.

4.Firestop System — The firestop system shall consist of the following:

A.Forms — (Not Shown) — Used to prevent the leakage of the fill material during the installation. Forms to rigid sheet material, cut to fit the contour of the penetrating items and fastened to the underside of the floor or both sides of the wall. Forms to be removed after the fill material has cured.B.Packing Material — (Not Shown) — Pieces of mineral wool insulation firmly packed between the cables or cable tray and the forms to prevent the leakage of the fill material while in its liquid state. Packing material may be removed after fill materials cured.C.Fill, Void or Cavity Material* — Mortar — Min 4-1/2 in. thickness of fill material applied within the annulus flush with the top surface of the floor or with both surfaces of wall. During the installation of fill material, cables are to be pulled apart and fill material to be forced into the interstices of cables and within the annular space between cables and cable tray to max extent possible. Mortar to be mixed with water at a rate of 1.0 part dry mixture to 1.0 part water by weight in accordance with the installation instructions supplied with the product.

RECTORSEAL — FlameSafe® Mortar