C-AJ-3306

September 24, 2010

September 24, 2010

F Rating — 2 and 3 Hr (See Item 1)

T Rating — 0 Hr

L Rating At Ambient —Less Than 1 or 2.8 CFM/Device (See Item 2)

L Rating At 400 F — Less Than 1 or 1.6 CFM/Device (See Item 2)

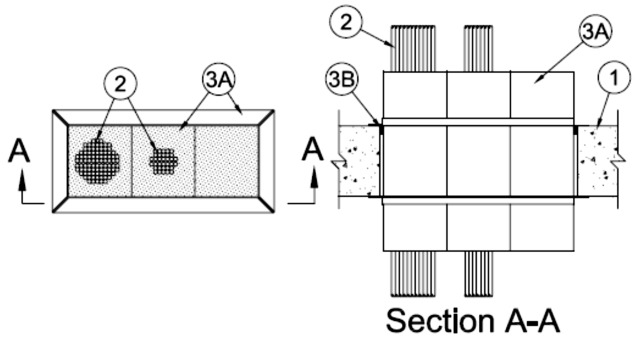

1.Floor or Wall Assembly — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is 50 in.2 (323 cm2) with a max dimension of 12-1/8 in. (30 mm) for square devices. When thickness of floor or wall assembly is less than 4-1/2 in. (114 mm), F Rating is 2 hr.

See Concrete Blocks (CAZT) category in Fire Resistance Directory for names of manufacturers.

2.Cables — Within the loading area of each firestop device module the cables may represent a 0 to 100 percent visual fill. Cables to be rigidly supported on both sides of floor or wall assembly. Any combination of the following types and sizes of cables may be used:

A.Max 2/C No. 18 AWG copper conductor thermostat cable with polyvinyl chloride (PVC) insulation and jacket materials. B.Max 4 pair No. 24 AWG copper conductor Cat5e or Cat 6 telephone cable with PVC insulation and jacket materials. C.Max RG/U (or smaller) coaxial cable with foam high density polyethylene insulation and PVC jacket materials. D.Max 3/C (with ground) No. 14 AWG (or smaller) nonmetallic sheathed (Romex) cable with PVC insulation and jacket materials. E.Max 1/C No. 8 AWG copper conductor cable with PVC insulation and nylon jacket materials. F.Max 12 core No. 26 AWG shielded multi coax cable with foam high density polyethylene insulation and PVC jacket. G.Max 48MM62.5 micron fiber optic cables with having a min FT-6 rating. H.Max 62.5/125 micron fiber optic cables with having a min Riser rating. I.Max 1/C 3/0 AWG copper conductor cable with PVC insulation and jacket materials. J.Max three copper conductors (with ground) No. 12 AWG Metal Clad Cable+. K.Max four copper conductors No. 2 AWG Metal Clad Cable+. AFC Cable System Inc. L.Max 1/C 2/0 AWG non halogen copper conductor cable. M.Max 300 pair No. 24 AWG copper conductor telephone cable with PVC insulation and jacket materials. N.Max 30 pair No. 22 copper conductor shielded switchboard cable with PVC insulation and jacket materials. O.Max RG/6 (or smaller) coaxial cable with fluorinated ethylene (FE) or PVC insulation and jacket materials. P.Max RG/U (or smaller) coaxial cable with fluorinated ethylene (FE) or PVC insulation and jacket materials. Q.Max 7/C No. 12 AWG copper conductors with PVC insulation and jacket materials. R.Max 4 pair No. 23 AWG copper conductor Cat 6 telephone cable with PVC insulation and jacket materials. S.Max 04-02 2 5M fiber optic cables having a max diameter of 0.450 in. (11.4 mm). T.Max 1/C No. 750 kcmil copper conductors with PVC insulation and fabric jacket materials. U.Max 3/C with ground No. 2/0 AWG aluminum conductor SER cable with cross linked polyethylene (XLPE) insulation and PVC jacket. L Rating is less than 1 CFM/Device for a single cable or a blank at ambient and at 400 F. The L Rating is 2.8 CFM/Device and 1.6 CFM/Device at ambient and at 400 F, respectively, for all other percentages of fill.

3.Firestop System — The firestop system shall consist of the following:

A.Firestop Device* — A max of three square firestop devices may be ganged together. As an alternate, one round device may be centered within a round opening. Each device consists of a nom 2-1/2 by 2-1/2 by 10 in. (64 by 64 by 254 mm), a nom 4 by 4 by 10 in. (102 by 102 by 254 mm), a nom 2 in. (51 mm) diam by 10 in. (254 mm) or a nom 4 in. (102 mm) diam by 10 in. (254 mm) powder coated steel transit incorporating internal intumescent material, foam plugs and mounting flanges. Firestop device to be centered within opening and installed with ends projecting an equal distance beyond each surface of the floor or wall assembly in accordance with the accompanying installation instructions. The annular space between the firestop device(s) and the periphery of the opening shall be nom 1/8 in. (3 mm). Firestop devices secured in place by means of fill material (Item 4B) and steel split mounting flanges sized to accommodate the firestop device. Steel split mounting flanges installed on both sides of floor or wall after installation of fill material and secured to together with supplied steel set screws. Nom 1-1/2 in. (38 mm) thick pre-cut foam plugs sized to accommodate the cable bundle and installed flush with each end of device on both sides of floor or wall assembly. When cables are installed at a 100% visual fill, the plug may be trimmed to fit the interstices of the cables and the perimeter of the device.

RECTORSEAL — Metacaulk® 2-1/2" square Pass Through Device, Metacaulk® 4" square Pass Through Device, Metacaulk® 2" round Pass Through Device, Metacaulk® 4" round Pass Through DeviceB.Fill, Void or Cavity Materials* - Caulk or Putty — Min 1/8 in. (3 mm) thickness of caulk or min 1/2 in. (13 mm) thickness of putty applied within the annulus, flush with top surface of floor or with both surfaces of wall prior to the installation of the mounting flanges. An additional bead of caulk shall be placed between ganged devices on both sides of floor or wall when multiple devices are used.

RECTORSEAL — Metacaulk 1000 or Fireputty pad.

+ Bearing the UL Listing Mark