C-AJ-3241

July 16, 2014

July 16, 2014

| ANSI/UL1479 | CAN/ULC S115 |

|---|---|

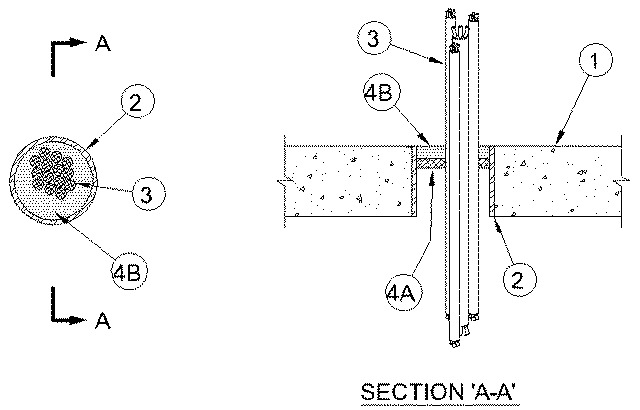

1.Floor or Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Floor may also be constructed of any min 6 in. thick UL Classified hollow-core Precast Concrete Units*. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 6 in.

See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) categories in the Fire Resistance Directory for names of manufacturers.

2.Metallic Sleeve — (Optional) — Nom 6 in. diam (or smaller) Schedule 10 (or heavier) steel sleeve cast or grouted into floor or wall assembly, flush with floor or wall surfaces.

3.Cables — Aggregate cross-sectional area of cables in sleeve or opening to be max 19.3 percent of the cross-sectional area inside the sleeve/opening or a max 2-9/16 in. diam cable bundle may be used. The annular space between cables and periphery of opening shall be min of 0 in. (point contact) to max 3-1/8 in. Cables to be bundled together and rigidly supported on both sides of floor or wall assembly. Any combination of the following types and sizes of cable may be used:

A.Max 400 pairs, 24 AWG telephone communication cable with PVC insulation and jacket. B.Max 62.5/125 fiber optic cable with PVC insulation and jacketing. C.Max 4/C No. 2/0 AWG (or smaller) aluminum or copper conductor aluminum or steel jacketed Metal-Clad or Armored-Clad cable. D.Max 7/C No. 12 AWG copper conductor power and control cables; XLPE or PVC insulation with XLPE or PVC jacket. E.Max RG59/U (or smaller) coaxial cable with fluorinated ethylene insulation and jacketing. F.Type RG 59/U coaxial cable with polyethylene (PE) insulation and PVC jacket.

4.Firestop System — The details of the firestop system shall be as follows:

A.Packing Material — Min 1 in. thick backer rod, mineral wool or fiberglass batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from top surface of floor or both surfaces of wall as required to accommodate the required thickness of fill material. When the floor is constructed of hollow-core precast concrete units, packing material shall be installed symmetrically on both sides of floor and recessed from both floor surfaces.B.Fill, Void or Cavity Materials* — Min 1in. thickness of fill material applied within annulus, flush with top surface of floor or both surfaces of wall assembly. When the floor is constructed of hollow-core precast concrete units, fill material shall be installed symmetrically on both sides of floor, flush with both floor surfaces.

RECTORSEAL — FS 900+ Sealant, Metacaulk MC 150+, Biostop BF 150+