C-AJ-3087

April 12, 1995

April 12, 1995

F Rating — 3 Hr

T Rating — 2 Hr

L Rating At Ambient — 1525 CFM/sq ft

L Rating At 400 F — Less Than 1 CFM/sq ft

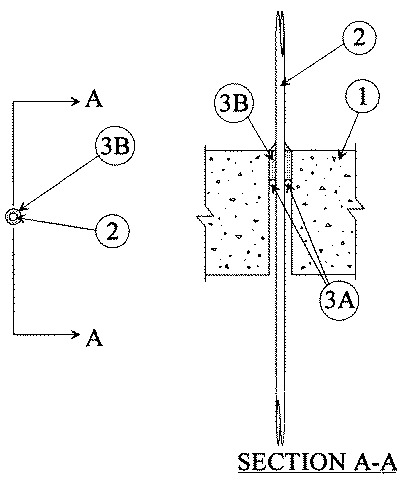

1.Floor or Wall Assembly — Min 4-1/2 in. thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 1/2 in.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Cables — One cable to be installed either concentrically or eccentrically within the firestop system. Cables to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of copper conductor cables may be used:

A.Max 25 pair No. 24 AWG (or smaller) polyvinyl chloride (PVC) insulated and jacketed telephone cables. The annular space shall be min 1/16 in. to max. 1/8 in. B.Max 3/C W/Ground No. 12 AWG cable with PVC insulation and jacket. The annular space shall be min 0 in. to max 1/8 in.

3.Firestop System — The firestop system shall consist of the following:

A.Packing Material — (Optional) — Foam backer rod firmly packed into opening as a permanent form. Packing material to be recessed from top surface of floor or from both surfaces of wall as required to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* — Sealant — Fill material to be forced into the annulus to maximum extent possible on top surface of floor or both surfaces of wall. Additional fill material to be installed such that a min 1/4 in. crown is formed around the penetrating item and top surface of floor or both surfaces of wall.

RECTORSEAL — Metacaulk 1000.