December 22, 2023

December 22, 2023

|

ANSI/UL1479 (ASTM E814) |

CAN/ULC S115 |

|

F Rating — 2 Hr |

F Rating — 2 Hr |

|

T Rating — 0 Hr |

FT Rating — 0 Hr |

|

L Rating At Ambient — Less Than 1 CFM/ft2 |

FH Rating — 2 Hr |

|

L Rating At 400°F — Less Than 1 CFM/ft2 |

FTH Rating — 0 Hr |

|

W Rating - Class 1 (See Item 3B and 3C) |

L Rating At Ambient — Less Than 5.1 L/s/m2 |

|

|

L Rating At 204°C— Less Than 5.1 L/s/m2 |

System tested with a pressure differential of 2.5 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side.

System tested with a pressure differential of 50 Pa between the exposed and the unexposed surfaces with the higher pressure on the exposed side. (See Item 2)

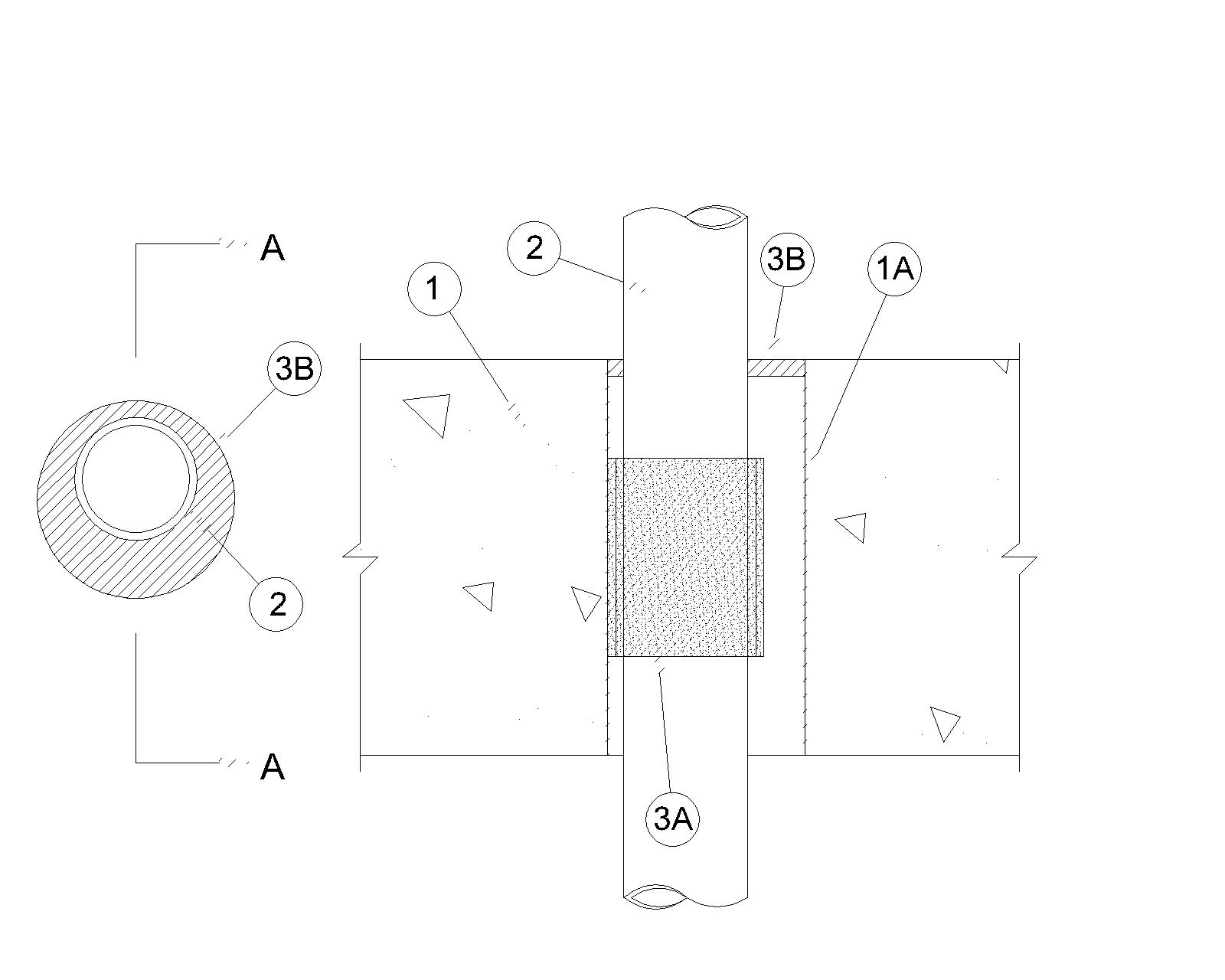

1. Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100 - 150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Floor may also be constructed of any 6 in. (152 mm) thick UL Classified hollow core Precast Concrete Units*. When hollow core Precast concrete is used the max diam of opening is 6 in. (152 mm).

See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers.

1A. Metallic Sleeve — Required for use with Concrete Blocks or hollow core Precast Concrete Units, optional for solid block or solid wall construction. Nom 7 in. (178 mm) Diam (or smaller) cylindrical sleeve fabricated from min 0.018 in. (0.46 mm) thick (28 gauge) galv sheet steel and having a min 1 in. (25 mm) lap along longitudinal seam. Length of sleeve to be installed flush with wall surfaces.

2. Through Penetrant — One nonmetallic pipe to be installed concentrically or eccentrically within the firestop system. Annular space within the firestop system is dependent upon the max diam and type of penetrant as shown in Table 1. When W Rating applies, annular space shall be a min 1/2 in. (13 mm). Pipe to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of nonmetallic pipes may be used:

A. Polypropylene (PP-R) Pipe — Nom 8 in. (203 mm) diam SDR 11 or Nom 6 in. (152 mm) (or smaller) Aquatherm or Niron with an SDR of 7.4, 9, 11, 17 or 17.6 pipe for use in closed (process or supply) or vented (drain, waste, or vent) piping systems. Pipes larger than 6 in. (152 mm) diam are restricted to SDR 11 only.

B Polypropylene (PP-RCT) Pipe — As an alternate to Item A, nom 8 in. (203 mm) diam SDR 11 or nom 6 in. (152 mm) (or smaller) Aquatherm or Niron with an SDR of 7.4, 9, 11, 17 or 17.6 pipe for use in closed (process or supply) or vented (drain, waste, or vent) piping systems. Pipes larger than 6 in. (152 mm) diam are restricted to SDR 11 only.

Penetrants A, B larger than nom 6 in. (152 mm) diam are limited to 2.5 Pa only for CAN/ULC - S115.

3. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Materials* — Nom 2 mm thick by 3 in. (76 mm) wide intumescent joint strip (See Table 1). Strips tightly wrapped around the outer circumference of the pipe with ends butted and held in place with tape. Joint strip slid into the annular space with the bottom edge of the joint strip recessed 3/4 in. (18 mm) from bottom surface of floor or 1-1/2 in. (38 mm) from both surfaces of wall.

Table 1:

|

|

Nom Diam In. (mm) |

layers |

Min Annular Space in. (mm) |

Max Annular Space in. (mm) |

In. (mm) |

Sealant Thickness In. (mm) |

|

A, B |

8(203) |

6 |

1/2 (12.7) |

1-5/8 (41.2) |

++10 (254) |

1/4 (6) |

|

A, B |

6(152) |

4 |

3/8 (9.5) |

1-3/8 (35) |

++8 (203) |

1/4 (6) |

|

A, B |

4(102) |

2 |

3/16 (4.8) |

1-1/4 (31.8) |

6 (152) |

1/4 (6) |

|

A, B |

3(76) |

1 |

1/16 (3.2) |

1-1/4 (31.8) |

4 (102) |

1/4 (6) |

++ opening diameters larger than 6 in. (152 mm) are not eligible for use in UL Classified hollow core Precast Concrete Units.

B.

RECTORSEAL — Metacaulk 1000, Metacaulk 150+, Metacaulk 350i, Biostop 500+, Biostop 350i.

C.