C-AJ-2783

February 17, 2017

February 17, 2017

F Rating — 2 Hr

T Rating — 2 Hr

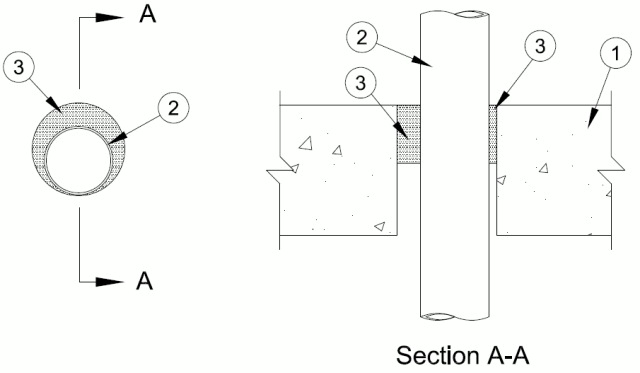

1.Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 4 in. (102 mm).

See Concrete Blocks (CAZT) in the Fire Resistance Directory for names of manufacturers.

2.Through Penetrants — One nonmetallic pipe to be installed concentrically within the firestop system. The annular space between the pipe and periphery of opening shall be min 1/2 in. (13 mm) to max 1 in. (25 mm). Pipe to be rigidly supported on both sides of the floor or wall assembly. The following types and sizes of nonmetallic pipes may be used:

A.Polypropylene (PP-RTC) Pipe — Nom 2 in. (63 mm OD) diam (or smaller) SDR 17 Niron pipe for use in closed (process or supply) piping systems.B.Polypropylene (PP-RTC) Pipe — Nom 2 in. (63 mm OD) diam (or smaller) SDR 11 Niron pipe for use in closed (process or supply) piping systems.C.Polypropylene (PP-RTC) Pipe — Nom 2 in. (63 mm OD) diam (or smaller) SDR 7.3 Niron pipe for use in closed (process or supply) piping systems.

3.Fill, Void or Cavity Materials* — (Caulk) - Min 2 in. (51 mm) thickness of caulk applied within the annulus, flush with top surface of floor or both surfaces of wall.

RECTORSEAL — Metacaulk 1000, Metacaulk 350i, Biostop 500+, Biostop 350i or FlameSafe 1900