December 6, 2023

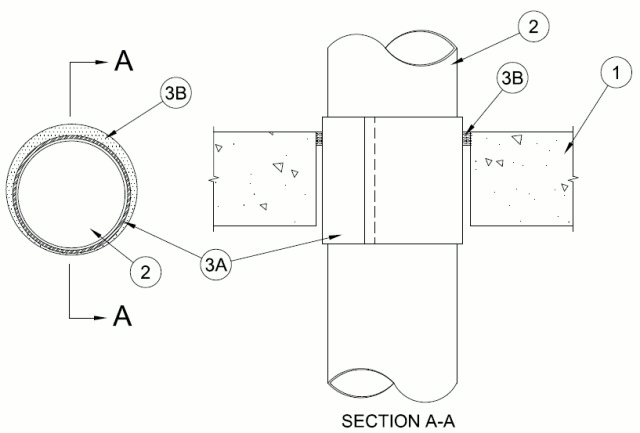

1.Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Floor may also be constructed of any min 6 in. (152 mm) thick UL Classified hollow-core Precast Concrete Units*. If the firestop system is installed within a hollow-core precast concrete unit, max diam of opening shall be 7 in. (178 mm). Otherwise, max diam of opening is 8 in. (203 mm).See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) categories in the Fire Resistance Directory for names of manufacturers.

1A.Steel Deck/Floor Assembly — (Not Shown) — As an alternate to Item 1, the floor assembly may consist of a fluted steel deck/concrete floor assembly. The floor assembly shall be constructed of the materials and in the manner described in the individual Floor-Ceiling Design in the UL Fire Resistance Directory and shall include the following construction features:A.Steel Floor and Form Units* — 1-1/2 to 3 in. (38 to 76 mm) deep galv fluted units. Max diam of opening is 8 in. (203 mm).B.Concrete — Min 4-1/2 in. (114 mm) thick reinforced concrete, as measured from the top plane of the floor units. Max diam of opening is 8 in. (203 mm).

2.Through Penetrants — One nonmetallic pipe to be installed concentrically within the firestop system. The annular space between the pipe and periphery of opening shall be max 7/8 in. (22 mm). Pipe to be rigidly supported on both sides of the floor or wall assembly. The following types and sizes of nonmetallic pipes may be used:A.Polypropylene (PP-R) Pipe — Nom 6 in. diam - 160 mm OD (or smaller) SDR 17.6 MF Aquatherm Blue Pipe for use in closed (process or supply) piping systems.B.

Polypropylene (PP-R CT) Pipe — Nom 6 in. diam - 160 mm OD (or smaller) SDR 17 Niron Clima Pipe or Niron CoolPro Pipe for use in closed (process or supply) piping systems.C.

Polypropylene (PP-R) Pipe — Nom 4 in. diam - 125 mm OD (or smaller) SDR 7.4 and SDR 11 MF Aquatherm Blue Pipe for use in closed (process or supply) piping systems.D.

Polypropylene (PP-RCT) Pipe — Nom 4 in. diam - 125 mm OD (or smaller) SDR 7.4 and SDR 11 Niron Clima Pipe for use in closed (process or supply) piping systems.E.

Polypropylene (PP-R) Pipe — Nom 4 in. diam - 125 mm OD (or smaller) SDR 7.4 and SDR 11, MF and S, Aquatherm Green Pipe for use in closed (process or supply) piping systems.F.

Polypropylene (PP-RCT) Pipe — Nom 4 in. diam - 125 mm OD (or smaller) SDR 7.4 and SDR 11, Niron CoolPro or SDR 11 Niron Nero Pipe for use in closed (process or supply) piping systems.

3.Firestop System — The firestop system shall consist of the following:A.Firestop Device — Galv steel sleeve lined with an intumescent material sized to fit the specific diam of the through penetrant. Intumescent Sleeve 234 to be used with pipe sizes of nom 4 in. (or smaller). Intumescent Sleeve 68 to be used with pipe sizes exceeding nom 4 in. diam. Device to be installed in accordance with the manufacturer\'s installation instructions along with the following: Device to be wrapped around outer circumference of through penetrant and installed through the annular space of the opening. The device may be temporarily secured together by means of tape or tie wires around the outer circumference of through penetrant to allow for installation of the fill material (Item 3B). The device shall be centered within the floor or wall and extend equally beyond each surface of the floor or wall.

RECTORSEAL — FlameSafe® Intumescent Sleeve, Metacaulk Intumescent Sleeve or Biostop Intumescent SleeveB.Fill, Void or Cavity Material* — Sealant — Min 1/2 in. (13 mm) thickness of fill material applied within the annulus, flush with top surface of floor or both surfaces of wall. When hollow-core precast concrete unit is used, min 1/2 in. (13 mm) thickness of fill material applied within the annulus, flush with both surfaces of floor.

RECTORSEAL — Metacaulk 1000, Metacaulk 150+, Biostop 500+, Biostop 150+, FlameSafe 1900