C-AJ-1528

July 15, 2014

July 15, 2014

| ANSI/UL1479 (ASTM E814) | CAN/ULC S115 |

|---|---|

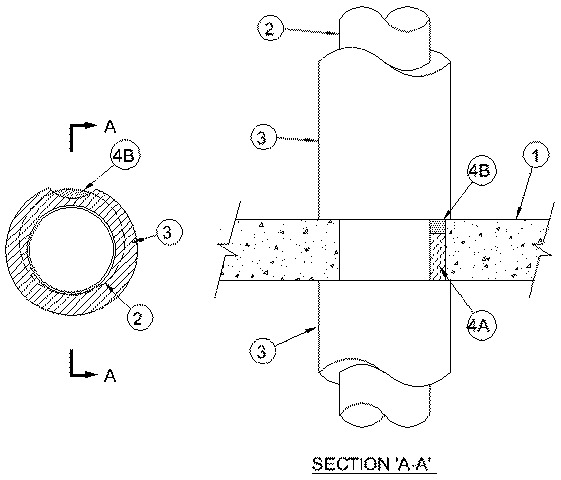

1.Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3 ) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Floor may also be constructed of any 6 in. (152 mm) thick UL Classified hollow-core Precast Concrete Units*. Max diam of opening 14 in. (356 mm). When precast concrete units are used the max diam of opening is 7 in. (127 mm).

See Concrete Blocks (CAZT) and Precast Concrete Units* (CFTV) categories in Fire Resistance Directory for names of manufacturers.

2.Through-Penetrant — One metallic pipe or tubing installed concentrically or eccentrically within opening. Annular space between penetrant and periphery of opening shall be min of 0 in. (point contact) to max 1-1/4 in. (32 mm) for steel/iron through penetrants and max 2 in. (51 mm) for copper through penetrants. Penetrant to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of penetrants may be used:

A.Steel Pipe — Nom 12 in. (305 mm) diam (or smaller) Schedule 40 (or heavier) steel pipe.B.Iron Pipe — Nom 12 in. (305 mm) diam (or smaller) cast or ductile iron pipe.C.Steel Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 5 (or heavier) steel pipe.D.Copper Tubing — Nom 4 in. (102 mm) diam (or smaller) Type L (or heavier) copper tubing.E.Copper Pipe — Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.When penetrant diameter is 4 in. (102 mm) or smaller the T Rating is 2 h. When penetrant diameter is greater than 4 in. (102 mm) the T Rating is 1-3/4 h.

3.Pipe Covering Materials* — (Partial Insulation) — Max 2 in. (51 mm) thick unfaced mineral fiber pipe insulation having a nom density of 4 pcf (64 kg/m3) (or heavier) and sized to fit the outside diam of pipe or tube. Pipe insulation installed around penetrant and shall extend 12 in. (305 mm) below floor and 36 in. (914 mm) above floor or 36 in. (914 mm) beyond both surfaces of wall. Pipe insulation secured with min 8 AWG steel wire spaced 12 in. (305 mm) OC. All longitudinal and transverse joints to be sealed with 4 in. (102 mm) wide aluminum foil tape.

INDUSTRIAL INSULATION GROUP L L C — High Temperature Pipe Insulation 1200, High Temperature Pipe Insulation BWT and High Temperature Pipe Insulation Thermaloc

4.Firestop System — The details of the firestop system shall be as follows:

A.Packing Material — Min 4 in. (102 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form. Packing material to be recessed from top surface of floor or from both surfaces of wall to accommodate the required thickness of fill material.B.Fill, Void or Cavity Materials* - Sealant — Min 1/2 in. (13 mm) thickness of sealant applied within the annulus, flush with top surface of floor or with both surfaces of wall. In floors of precast concrete units, sealant shall be installed symmetrically on both sides of the floor.

RECTORSEAL — FS 900+ Sealant, Metacaulk MC 150+, Biostop BF 150+